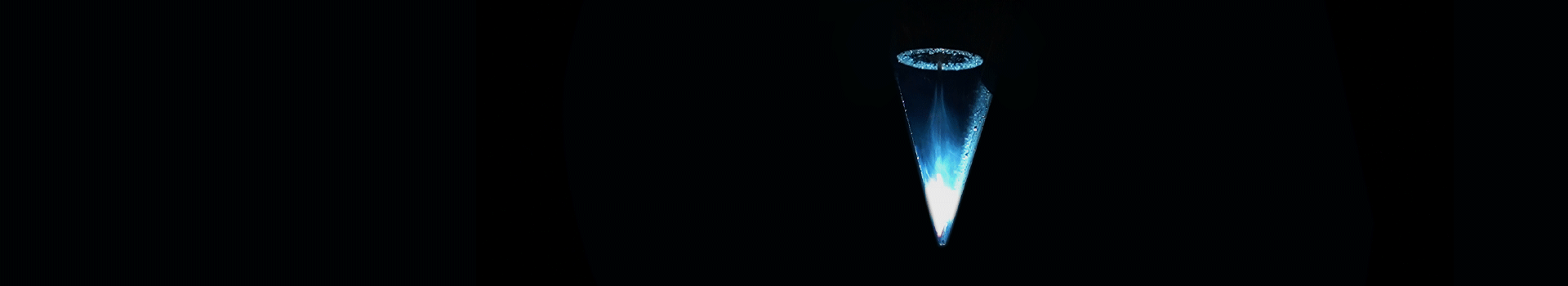

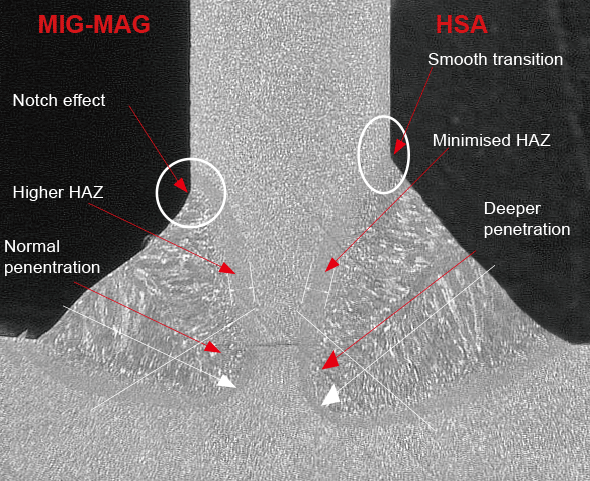

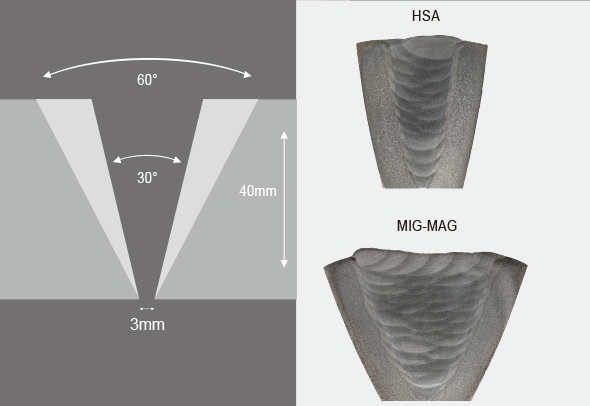

HSA, the High-Speed Spray Arc, stands out by its perfect combination of a highly concentrated and extremely stable arc with higher density. HSA delivers deeper penetration, narrower heating zone,less distortion and undercuts, allowing smaller opening angles for narrow gap welding and multi-pass welding, significantly improves the welding speed up to 30% faster than conventional MIG-MAG welding. It makes welding more efficient and more economical.

- • More concentrated arc

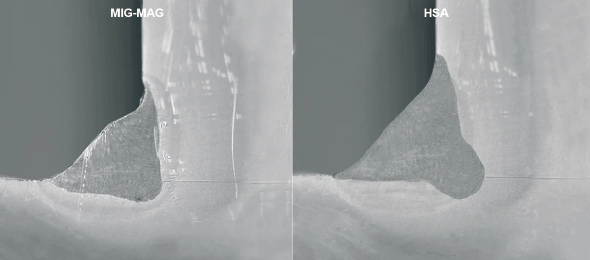

• HSA has been transmitting energy in the form of spay at a hig level, while the shorter arc length further compresses the arc, resulting in more concentrated energy, more directional arc, and deeper penetration;

• The compressed arc can better control the heat, and the arc has a smaller range, resulting in less heat -affected areas and deformation, ideal for multi -layer welding applications.

- • More stable arc

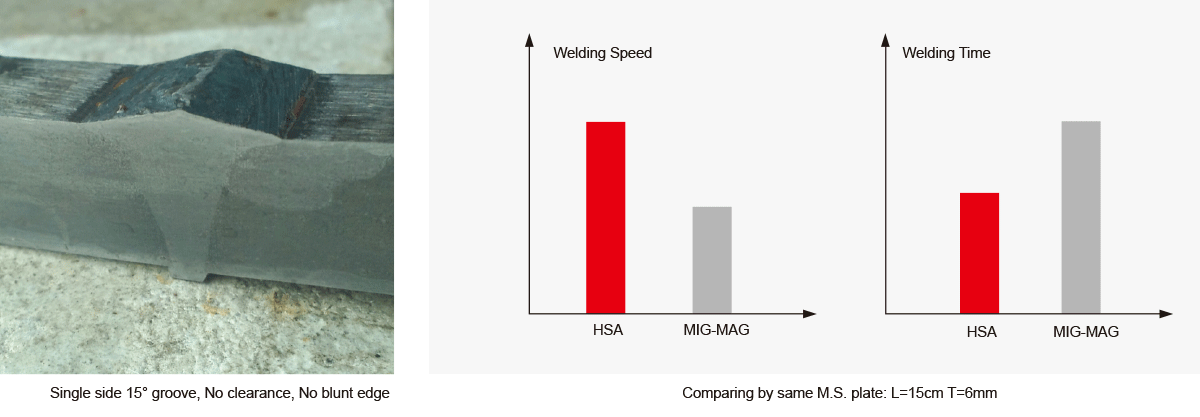

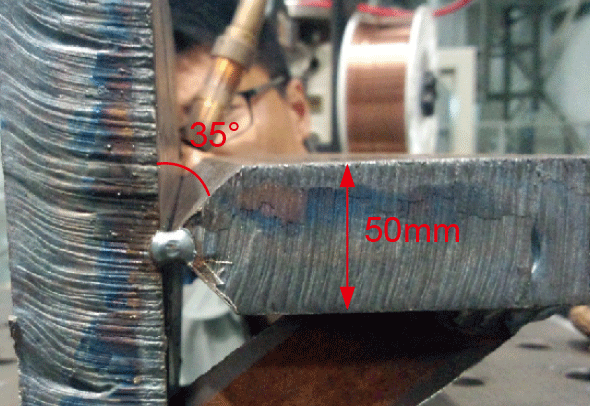

30° is entirely sufficient a weld prep to weld a proper seam. This helps conserve both valuable time and precious material.

The wire extension can reach 4cm, and the arc stability is not changed by the change of wire extension, which is more suitable for narrow seam welding.

- • Higher welding efficiency

Up to 10 times welding speed than conventional MIG/MAG welding.

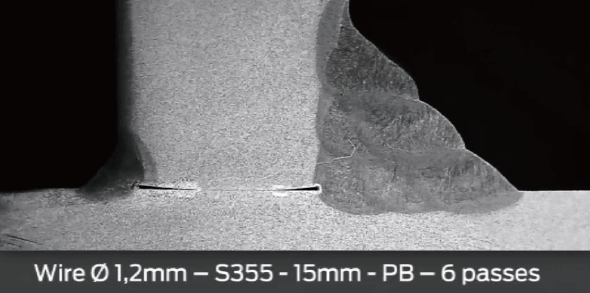

One-side welding with back formation for thin plat, up to 15mm thick could be joined in one single pass.