Welding

HSP: High Speed Pulse Transfer

ULS: Ultra Low Spatters Control

HSS: High Speed Spot Arc

HPC: Hybrid Pulse Control

HSP: High Speed Pulse Transfer

ULS: Ultra Low Spatters Control

HSS: High Speed Spot Arc

HPC: Hybrid Pulse Control

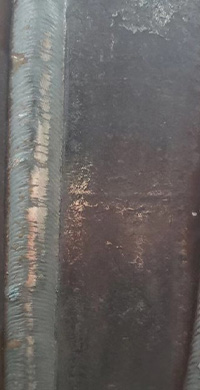

The new ULS process is a modified dip transfer arc with extremely high arc stability. The user can achieve high-quality weld seams with minimal spattering and an increased deposition rate, even in an intermediate and spray arc.

It is the highest form of plasma technology. With Gas Console for O2/Air/N2/H35, it builds on high definition plasma and sets new standards for cut quality on mild steel, stainless steel, and aluminum.

TOPWELL Hybrid Pulse Control, it mixes Pulse(spray arc) and short-circuit transfer types inone duty cycle. With the outstanding process, it keeps the advantage of both transfer types and provides a great performance for all pipe

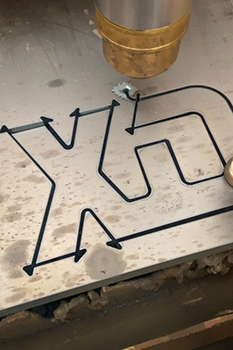

Comparing with the standard spot welding, High Speed Spot is an great improvement. It offers a faster travel speed and better welding performance, especially for thin (less than 2mm) pipes or frame/structure welding jobs, like the furnitures etc.

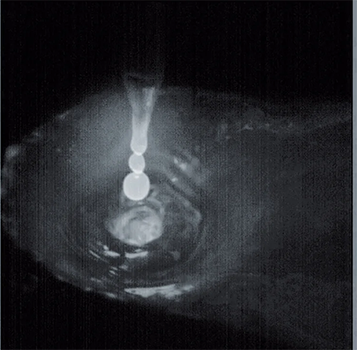

In general, One pulse melt one droplet, but we increase the submission of these droplets by TOPWELL’s New High-Speed pulse process. The transition will be faster, narrower HAZ zone and deeper penetration!

It deliver High Definition cut quality at half the operating costs. High Definition CuttingMaximized ProductivityLong-life Consumables

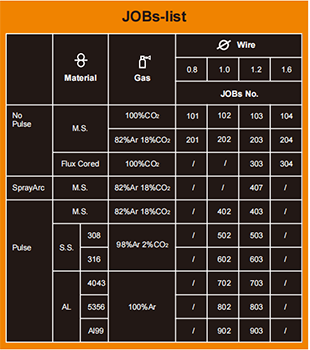

After thousands of welding test, TOPWELL put all the experience into the new Synergy system, Jobs-list. It is assembled the perfect welding curve in every Job number for high quality welding of steel, stainless steel and aluminum alloys. Operation is much easier than ever.

The popular ALUMIG series came out. Based on Pulse MIG, TOPWELL create the double pulse MIG in it. It is featured to weld aluminum. Without swing, you can easily get an stacked-dime joint.

The popular MASTERTIG series came out. It not only has advanced DC TIG& AC TIG, but also has TOPWELL unique MIX TIG. It is an improvement from AC TIG which has both AC current and DC current in one duty cycle. And it has deeper penetration, better arc concentration and less tungsten consumption.

After learning and tested by time, TOPWELL updated the new soft-switching IGBT system as a main structure of the machines. It was proved as great reliability and stability.

In Summer, Mr. Robin Yan founded the Broad Industrial Group at Hangzhou, which called paradise of China. Aiming to offer TOP products, TOP service and TOP technologies, he decided to name the new brand as “TOPWELL”.

To be the welding & cutting expert.

To be the world top brand.

To make welding & cutting more and more simple.

To make every welder & cutting lovers able to use toptechnologies.

To assemble a capable and well trained crew that is interestedand satisfied with their work and loyal to the company and totheir fellow employees.

To provide stable employment,good working conditions and thebest wage and benefit package that economic conditions allow.

To maint ain our reputation for the finest quality products andthe best service available anywhere.

To earn a reasonable profit.