Home / All / Welding Equipment / MIG Welders /

STEELMATE PRO 500 comprised of a variety of advanced welding processes heavy duty mig welders

STEELMATE PRO 500 comprised of a variety of advanced welding processes heavy duty mig welders

Experience Excellence in Welding with STEELMATE 500. Discover the Versatility of Heavy Duty MIG Welders.

Detail Information

DETAILS

STEELMATE PRO SERIES

Ultra high deposition, Flexible operation methods, Compact wire feeder

Quick Specs

|

Steelmate po Series

|

Steelmate pro 500 |

|

Input Voltage

|

3PH ~ 400V ±15% |

|

Rated Output(40℃) 60% |

500A/39V |

Cooling system | Air-coole |

Equipment

|

Welding process package

|

|

|

HSP (High Speed Pulse)

|

●

|

HSA (High-Speed Spray Arc) | ● |

ULS (Ultra Low Spatter) | ○ |

HPC (Hybrid Pulse Control) | ○ |

UCA (Ultra oncentrated Arc) | ○ |

HSS (High Speed Spot) | ○ |

Operational Method | |

At the remote control | ● |

At the wire feeder | ● |

At the remote control unit | ○ |

● Standard ○Optional

Simple operation

• 3 Steps To Achieve Weld Perfection

① Select operation mode.

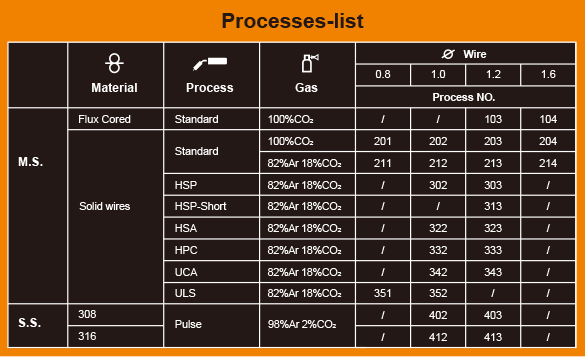

② Select Processes-list No. (Welding process)

③ Adjust welding current.

(always the perfect setting by the synergic function using the material thickness)

• Synergy control With Processes-list

The Processes-list display is easily and intuitively controlled through its graphical user interface. We assem bled the perfect welding curve in every Process-No. to help the users choose the best welding process for carbon steels, aluminum alloys and stainless steel. Operation is easier than ever before.

• Memory storage function

Users will have a variety of welding needs and hope to set the most suitable welding parameters for different materials and workpieces. Steelmate PRO Series has memory storage function, up to 999 independent welding tasks (Jobs) to maintain/save different welding operation parameters. Select and quickly restore previous settings with one click, making operation simpler and more efficient.

• Compact wire feeder delivery more flexible control methods

• The new designed compact, durable structure of the wire feeder make more confident and lighter to carry by users at heavy and tough workshops;

• The full-functional control panel at the wire feeder or remove off as remote controller delivery more flexibility of control methods.

• Ultra-long cable loop compensation function

Intelligent compensation makes welding more stable, especially suitable for oversized workpiece welding occasions,

with long-distance welding capabilities of up to 30 meters.

Capable for future intelligent fabrication

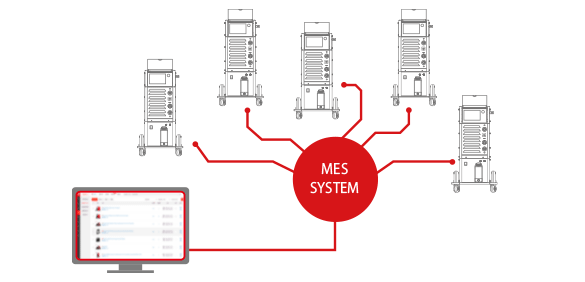

• Optional user management

Steelmate PRO series is equipped with with active user management and assigned NFC keys to set protection and permissions for parameter adjustment.

It can also choose to connect to the MES system, which is more suitable for modern production data management.

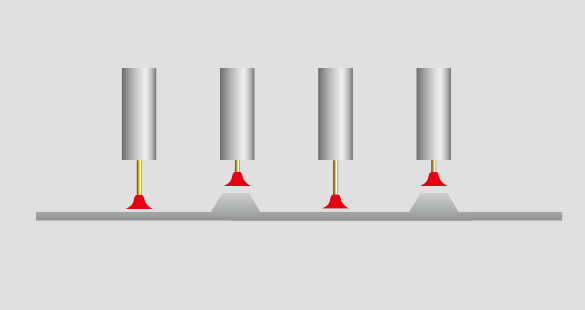

• Ready for robot welding

Robotic with advanced MIG process package, Steelmate PRO series achieve ultra-high efficient welding with perfect welding performance.

Using built-in communication protocols, there is no need to add additional external communication modules. Optional packages for robot interfaces are implemented through digital ports, including EtherNetlP, DeviceNet, CAN, CANOPEN, RJ485 etc.

Improved Operation Process & Controls

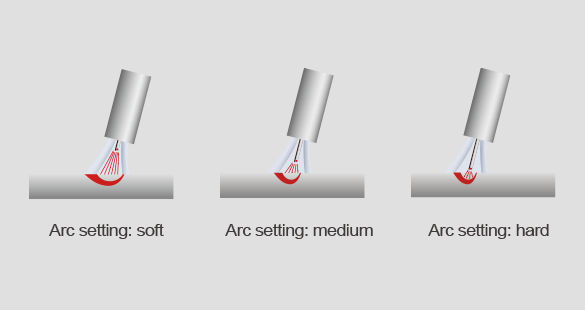

• Arc Length control

With the arc length control, no matter the changing distance between the torch and the workpiece, or the welding voltage, the arc length is kept constant, and the seam quality and appearance remain unchanged.

• Dynamic control

The arc can easily be adjusted depending on the workpiece and positions as well as to the individual preferences of the welder through Dynamic Control. Changing the arc to soft or hard or anywhere in between, increases the reliability for a good root formation and side fusion even with a non-ideal position of the torch.

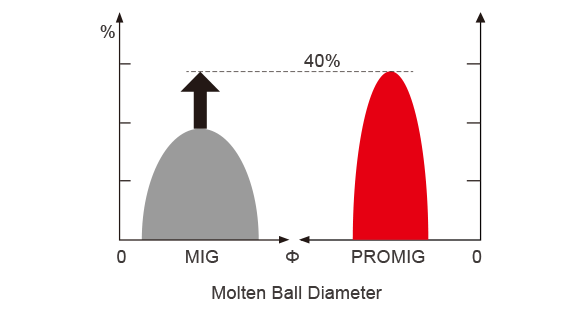

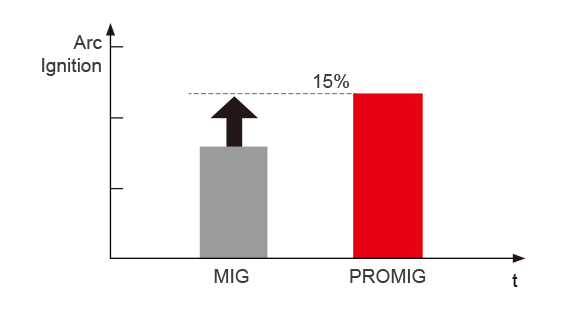

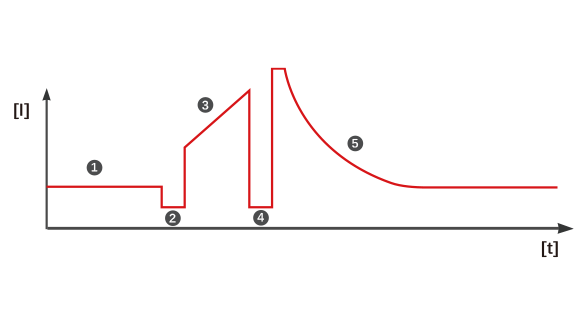

• Initial Arc control & Burn Back control

Initial Arc control is used to improve the success rate of arc ignition and form a smaller molten ball. Burn Back Control enhances the function of eliminating molten ball, making the secondary arc initial easier.

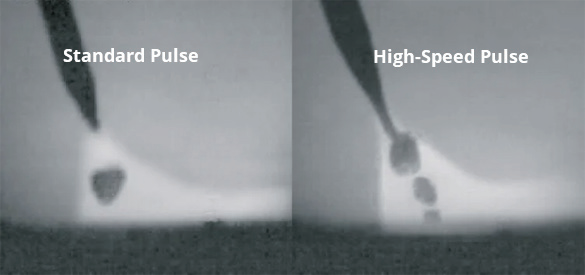

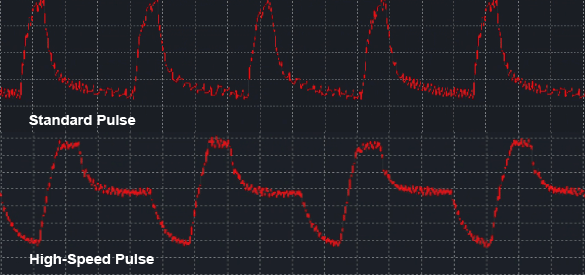

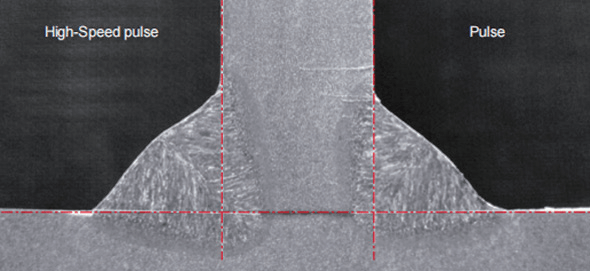

HSP - High Speed Pulse

-Specifically designed for demanding workshop use,the deposition rate can increase 25~48 % for various materials, whether used in manufacturing thick materials or sheet metal.

-The High-Speed Pulse(HSP) process enables you to save time, money, and energy compared to traditional pulse welding. This process is ready to raise pulse welding to a whole new level!

-In general, One pulse melt one droplet, but we increase the submission of these droplets by TOPWELL’ s New High-Speed pulse process.The transition will be faster, narrower HAZ zone and deeper penetration!

Get better welding seam

Less heat input, less spatters, less rework.

Get higher welding strength

Deeper penetration, no undercut defects, higher strength.

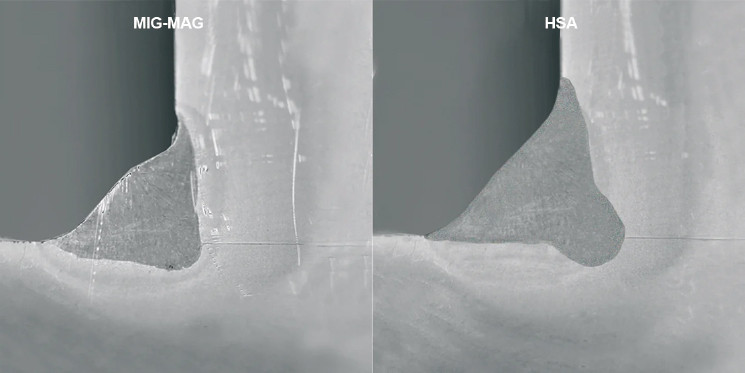

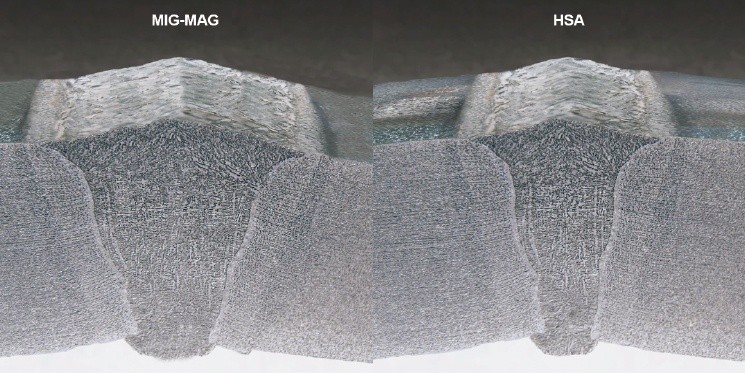

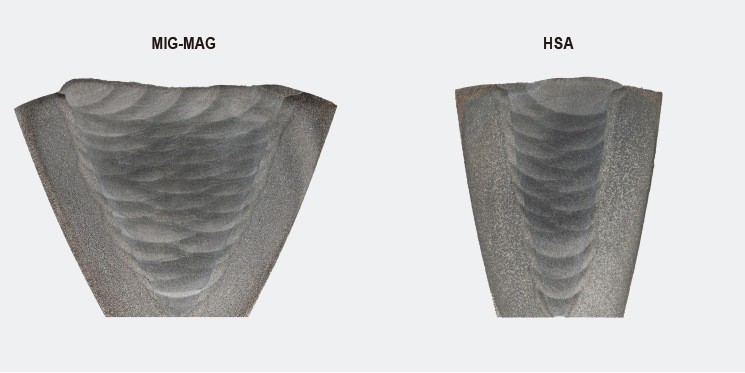

HSA - High Speed Spray Arc

The perfect combination of a highly concentrated and extremely stable arc with high density. HSA delivers deeper penetration, narrower heating zone, allows smaller opening angles for multi-layer welding, significantly improves the welding speed up to 30% faster than conventional MIG-MAG welding. It makes welding more efficient and more economical.

Smaller opening angle

Deeper penetration

More material saving

Higher welding efficiency

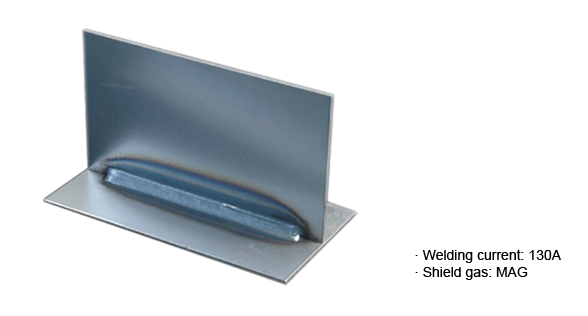

ULS - Ultra Low Spatters

The ULS process is a modified short-arc transfer arc, it controls the volatility during the change of state between short and arc to control the amount and size of the spatter generated. Even in CO2 and MAG welding, it can minimize the spatters, which means less rework, fewer rejects, less cleaning required and savings on wearing parts.

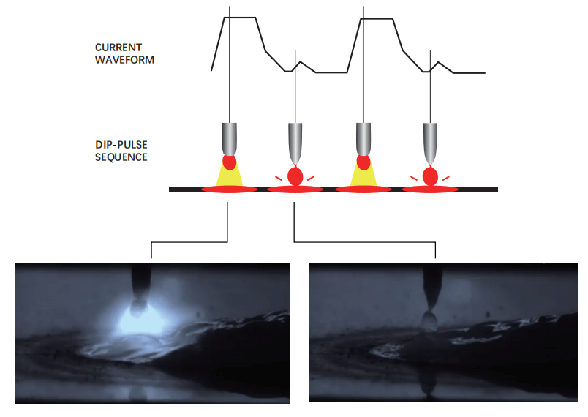

HPC - Hybrid Pulse Control

The key is synergetic waveform controlled welding process control variants applied in MIG welding which are Pulse(spray arc) and short-circuit transfer types in one duty cycle. It delivers exceptional directional stability, deep penetration and free-spatters.

HPC Vertical-up Welding Process

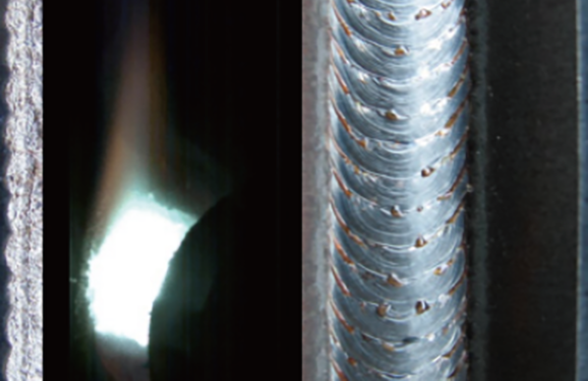

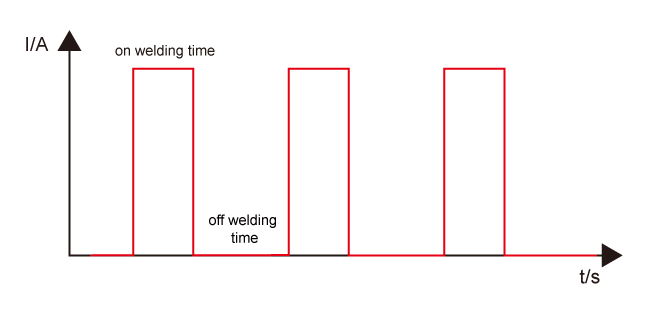

HSS - High Speed Spot Technology

HSS is the high speed spot welding, which is perfectly combining the welding process, arc physics, high dynamic power response and powerful motor control technology, short in arc ignition time and arc ending time, a welding spool can be formed swiftly. A spot welding cycle is quickly completed, cycle over and over, by adjusting the time gap with the robot to get the fish scale you wish, weld seam is clear and beautiful.

Tack welding: by robot

Widely applied on the thin (≤2mm thickness) pipes or frame/structure welding jobs.

VIDEO

SPECIFICATIONS

|

Product Name

|

STEELMATE PRO350 | STEELMATE PRO500 |

|

Mains voltage(V) |

3PH~400V±15%(50/60Hz) | 3PH~400V±15%(50/60Hz) |

|

Max.Load Power Capacity |

18.1KVA | 25.83KVA |

Output Range | MIG: 30A/15.5V~350A/31.5V | MIG: 30A/15.5V~500A/39V |

Rated Duty cycle at 40℃ (105℉): 60% | MIG: 350A/31.5V | MIG: 500A/39V |

100% | MIG: 250A/26.5V | MIG: 400A/31.5V |

Open Circuit Voltage | 70V~80V | 70V~80V |

Power Factor | 0.87 | 0.87 |

Efficiency | 89% | 89% |

Wire feed unit | 4 rollers | 4 rollers |

Wire feed speed range | 0~25m/min | 0~25m/min |

Wire SpoolCapacity | 300mm(15~20kg) | 300mm(15~20kg) |

Wires φ (mm): Fe | 0.8~1.2mm | 0.8~1.6mm |

Alu | 1.0~1.2mm | 1.0~1.2mm |

Flux-cored | 1.0~1.2mm | 1.0~1.6mm |

Dimension (L x W x H): Machine | 655 x 300 x 620 mm | 655 x 300 x 620 mm |

Wire feeder | 500 x 210 x 400 mm | 500 x 210 x 400 mm |

Net Weight : Machine | 45kg | 50kg |

Wire feeder | 12kg | 12kg |

YOU MAY ALSO NEED

ANY COMMENTS? YOU ARE WELCOME TO LEAVE MESSAGE TO US!

- Tel

- *Title

- *Content

Review

- Loading...