HSP

HIGH SPEED PULSE

Home / HSP

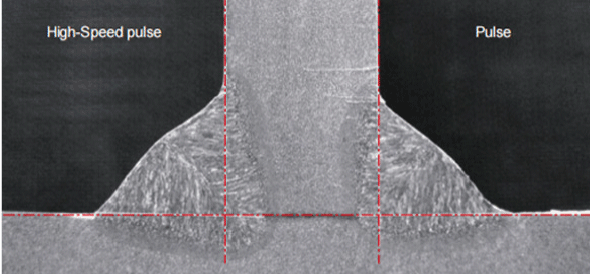

THE HIGH SPEED PULSE PROCESS

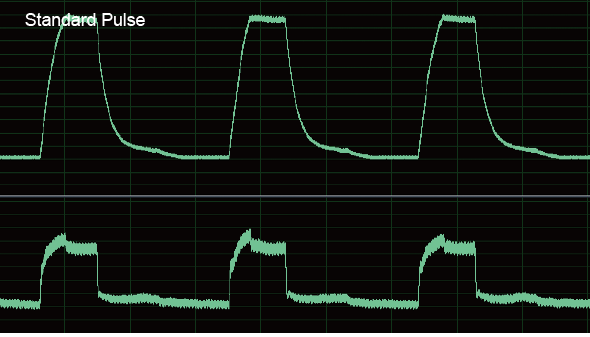

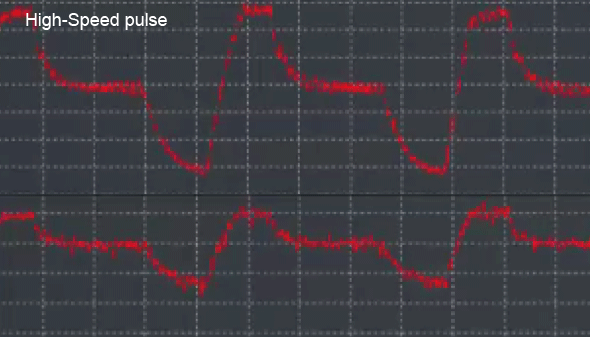

- This variant involves a modified I-U-I controlled, non-short-circuiting pulse welding process of constant frequency that marries the characteristics of the classic pulse arc with those of the classic spray arc in a beneficial way.

HSP - High Speed Pulse is a synergetic waveform controlled process control variant applied in MIG welding which is particularly well-suited for certain types of applications.

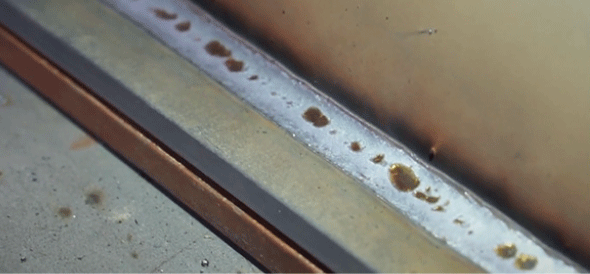

Combined with the extremely robust and stable arc properties, this improves handling and quality at little to no spatter, which leads to significantly less rework. Keep up with changing times when welding.

KEYFACTS

- • Up to 48% faster welding

- • Less heat input due to focused arc

- • 50% less noise due to pleasantly quiet arc

- • Excellent arc handling and visibility

- • Much less spatter, which equals less rework.

ADVANTAGES

- • Automation/Manual welding: High process reliability and intuitive arc length adjustment;

- • Melting capacity: Raising the upper limit of the deposition rate of the impulse process;

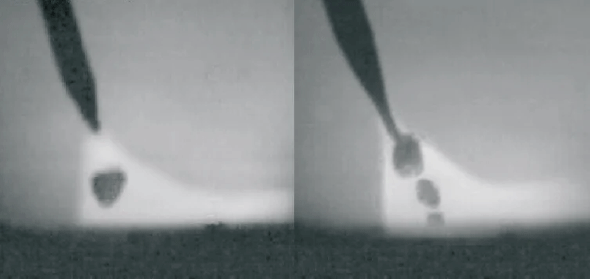

- • Penetration: Greater penetration depth;

- • Dynamics: Process effect adjustment options;

- • Ergonomics: Constantly pleasant pulse frequency, lower noise;

GET BETTER WELDING SEAM

Less heat input, less spatters, less rework.

GET HIGHER WELDING STRENGTH

Deeper penetration, no undercut defects, higher strength.

THE APPLICATIONS OF HSP

RELATED PRODUCTS

LET'S STAY IN TOUCH

Get updates on sales specials and more