Home / All / Plasma Cutting / All Product /

PROCUT-125MAX FACTORY USE CNC PLASMA CUTTING Machine single gas system

PROCUT-125MAX FACTORY USE CNC PLASMA CUTTING Machine single gas system

Delivering maximum power and performance for air plasma, the PROCUT 125MAX plasma system cuts thick metals fast.

Detail Information

DETAILS

PROCUT 125MAX

Delivering maximum power and performance for air plasma, the PROCUT 125MAX plasma system cuts thick metals fast. Able to make short work of the toughest cutting jobs, the system offers a 100% duty cycle, a 25 mm (1″) mechanized pierce capability. It’s comes with the PMX torch styles provide versatility for hand cutting, portable automation, X-Y table cutting, extended reach cutting, and robotic cutting.

CUTTING CAPACITY

|

Capacity

|

Thickness

|

Cut Speed

|

|

Cutting

|

||

|

Dross Free(CNC)

|

18mm

|

900mm/min

|

|

Severance (Hand Cutting)

|

60mm

|

125mm/min

|

Pierce | 25mm | |

*Pierce rating for handheld using or with CNC torch height control

Maximum Productivity

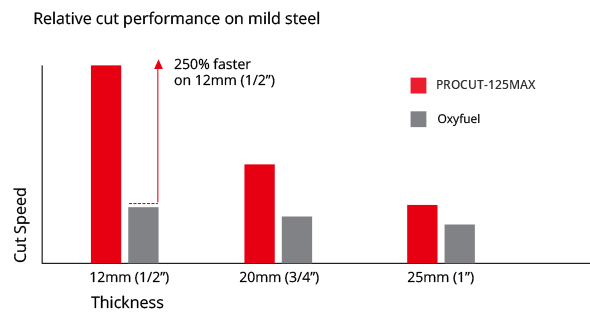

· Finish jobs faster with cut speeds five times greater than oxyfuel on 12 mm (1/2”) mild steel;

· Superior cut quality let you spend less time on grinding and edge preparation;

· 100% duty cycle maximizes your cutting time;

· Multiple, easy-to-use torch styles let you tackle a wide variety of jobs using the same system.

Superior Mechanized Cutting Capacity

· Fast and clean cut (dross-free) up to 18mm, and maxim pierce up to 25mm for mild steel;

· It can provide versatility for portable automation, X-Y table cutting, extended reach cutting, and robotic cutting.

Lower Operating Costs

· Consumable life up to four times longer than other systems in this amperage range;

· Electrode end-of-life detection protects the torch and workpiece from damage by automatically stopping power when the electrode is overused.

More Reliability And Stability

· Designed with 100% duty cycle for the most demanding production environments;

· Designed and tested as the TOPWELL PROCUT series product for superior reliability in the most demanding cutting environments.

Torch Information

For machine jobs

PMX125 180°, full-length machine torches work with a wide variety of CNC cutting tables, track cutters, and pipe-cutters. Mini machine torches are perfectly suited for lighter tables and pipe cutting situations where the full-length torch is too long.

PMX125 machine torches have a larger diameter and do not have a gear rack.

VIDEO

SPECIFICATIONS

Machines

|

Product Name

|

PROCUT 125MAX

|

Product Weights & Dimensions

|

Dimensions(L*W*H)

|

680*310*650mm

|

|

Net Weight

|

48KG

|

Basic Specification

|

Input Voltage

|

380V/400V, 3PH, 50/60Hz

|

|

Input Power

|

20.3KVA

|

Rated Output Voltage | 175VDC |

|

Max Output Current

|

125A

|

|

Open Circuit Voltage (OCV)

|

380VDC

|

Operating Temperature | -10℃~40℃ |

Duty Cycle Rating 40℃(105℉) | 125A@100% |

Torch | TP125/7.5m |

Recommended Gas Inlet Flow Rate/Pressure | 260 l/min (550 scfh) @ 5.9 bar (85 psi) |

YOU MAY ALSO NEED

air Regulator

TP125 Consumable Kit

PXM102

PXM102 Consumable Kit

Related Products

ANY COMMENTS? YOU ARE WELCOME TO LEAVE MESSAGE TO US!

- Tel

- *Title

- *Content

Review

- Loading...