Home / All / Welding Equipment / Multi-process Welders /

welding cutting machine 3 in 1 laser machine STC-205AC/DC

welding cutting machine 3 in 1 laser machine STC-205AC/DC

4-IN-1 Multi-precess:arc welding and plasma cutting machine price STC-205AC/DC

Detail Information

DETAILS

4-IN-1 Multi-process:

AC/DC TIG+Plasma Cutting

STC-205AC/DC

DC TIG - features the Pulse function, it precisely controls the welding arc, heat input and penetratoin.

AC TIG - with 2 kinds of AC waveshapes(square wave and sin wave), and 3 kinds of AC waveshape controls(Balance, Frequency and Amplitude).

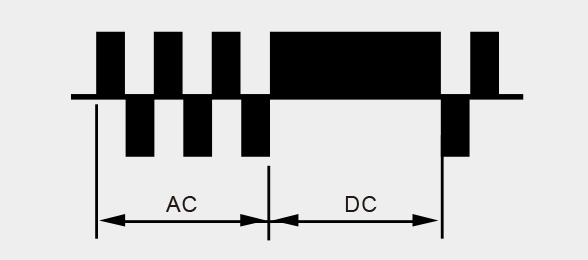

MIX TIG- has both AC current and DC current in one duty cycle, better arc concentration and deeper penetration.

Reliable and Powerful Design - 250A@60% duty cycle, capable for workshop jobs.

Cutting Capacity (Carbon Steel)

|

Capacity

|

Thickness(Cutting)

|

Cut Speed

|

|

Recommended

|

8mm |

500mm/min |

|

13mm

|

250mm/min

|

|

|

Severance(Hand Cutting)

|

16mm

|

125mm/min

|

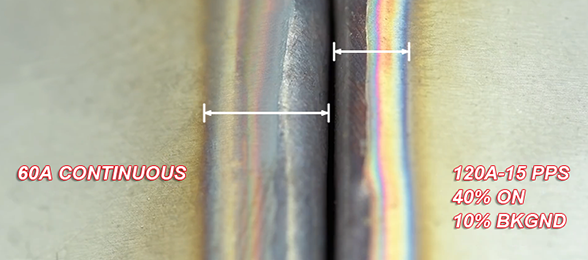

Advanced Pulse Controls

The Pulsed TIG function switches the amperage from a high (peak) to a low (background) at a set rate (PPS). Pulsing can reduce heat input by lowering the average amperage, increasing control of the weld puddle, penetration and distortion.

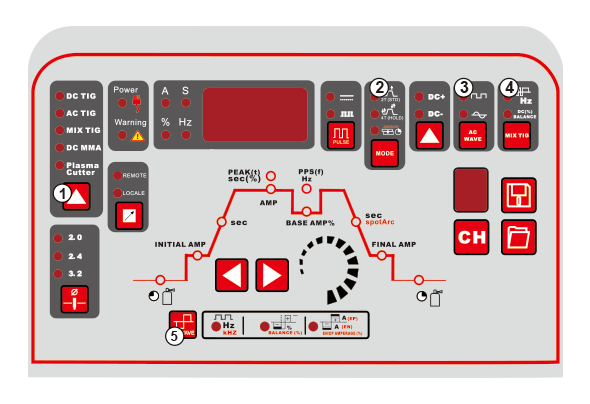

Control Panel Description

1. Welding Process

DC TIG/AC TIG/MIX TIG/DC MMA/Plasma Cutter

2. Pulser Control

3. AC Waveshape Types

Advanced Squarewave

Sin Wave

4. MIX TIG

5. AC Waveshape

AC Frequency Range 20Hz~200Hz

AC Clean Width (AC Balance) +40~-40

AC Clean Ratio (ACBias) % +30~-50

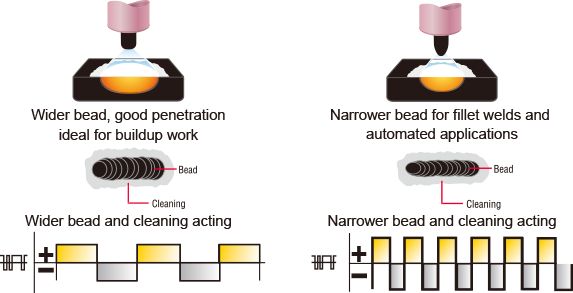

AC Frequency control

Controls the width of the arc cone. Increasing the AC Frequency provides a more focused arc with increased directional control.

Note: Decreasing the AC Frequency softens the arc and broadens the weld puddle for a wider weld bead.

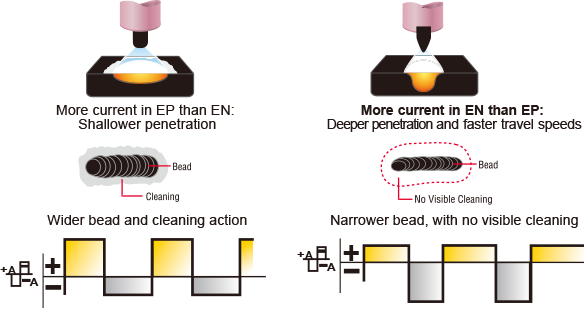

AC Balance Control

Controls arc cleaning action. Adjusting the % EN of the AC wave controls the width of the etching zone surrounding the weld.

Note: Set the AC Balance control for adequate arc cleaning action at the sides and in front of the weld puddle. AC Balance should be fine tuned according to how heavy or thick the oxides are.

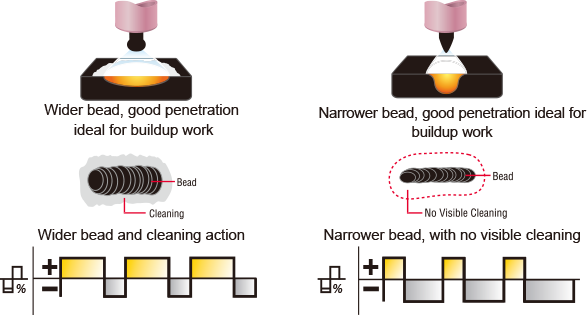

Amplitude Control

Adjusts the ratio of EN to EP amperage to precisely control heat input to the work and the electrode.

Note: EN amperage controls the level of penetration, while EP amperage dramatically effects the arc cleaning action along with the AC Balance control.

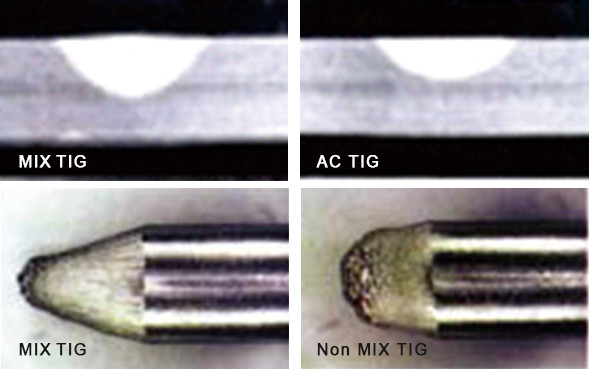

Unique MIX TIG

MIX TIG is TOPWELL's unique technology, it contains AC current and DC current in one duty cycle.That keeps the advantages and reduces disadvantages from each other. Using the MIX TIG technology gets an excellent arc concentration and can be carried out the excellent welding performance, especially for thick plates.

· Nice weld seam, Excellent arc concentration

· Deeper penetration

· Substantially reduce the tungsten consumption

VIDEO

SPECIFICATIONS

Machines

|

Product Name

|

STC-205AC/DC

|

|

Machines Processes

|

Stick (SMAW)

TIG (GMAW) Pulsed TIG (GTAW-P) Plasma Cutting |

Product Weights & Dimensions

|

Dimensions(L*W*H)

|

550x230x440mm

|

|

Net Weight

|

26kg

|

Basic Specification

|

Input Voltage

|

1PH ~ 230V ±15%

|

|

Max. Load Power Capacity

|

TIG: 5.63KVA MMA: 6.60KVA PAC: 8.20KVA |

|

Rated Duty Cycle(40℃) 60%

|

TIG: 200A/18V MMA: 160A/26.4V PAC: 50A/105V |

|

Welding Current/Voltage Range |

TIG: 5A/10.2V~200A/18V MMA: 20A/20.8V~160A/26.4V PAC: 20A/90A~50A/105V |

Open Circuit Voltage | TIG/MMA: 70V~80V PAC: 260V~290V |

YOU MAY ALSO NEED

Cart

ANY COMMENTS? YOU ARE WELCOME TO LEAVE MESSAGE TO US!

- Tel

- *Title

- *Content

Review

- Loading...