Home / All / Plasma Cutting / All Product /

220A PLASMA CUTTER CNC PLASMA CUTTING MACHINE HD 200W MECHANIZED USE

220A PLASMA CUTTER CNC PLASMA CUTTING MACHINE HD 200W MECHANIZED USE

The HD200W plasma cutting system is heavy duty and heavy capacity design. Cutting with Air/Air or Air/WMS

Detail Information

DETAILS

HD 200W

Heavy Duty, High Performance, Long Consumable Life Plasma Cutting System

Cutting Capacity

|

Mild Steel Cut Capacity

|

Thickness

|

|

Production Pierce

|

32mm |

|

Maximum Cutting Capacity

|

60mm

|

|

Stainless Steel Cut Capacity

|

Thickness

|

Production Pierce | 25mm |

Aluminum Cut Capacity | Thickness |

Production Pierce | 25mm |

High Performance Cutting

• HD200W plasma cutting system cuts fine-feature parts with superior quality and consistency, eliminating the cost of secondary operations.

• The focused plasma arc for more powerful precision cutting up to 32mm on Mild Steel and 25mm on Stainless steel and Aluminum.

• With water spray cutting process, the stainless steel and aluminum cutting will be less warping and produce a small heat-affected zone.

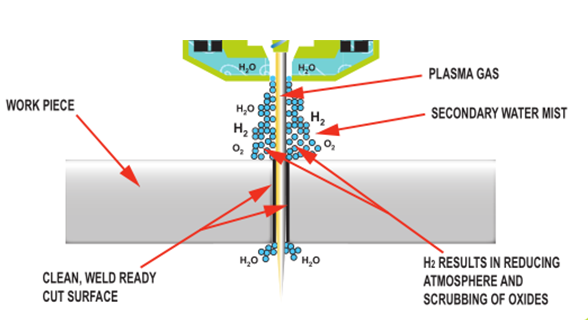

Water Mist Secondary (WMS) Technology

Long Consumable Life & Fast Cutting Speed

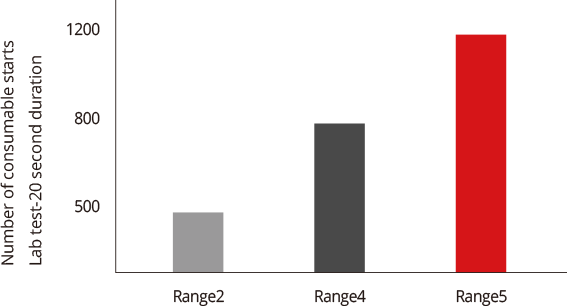

• 12mm mild steel;

• 200A Air/Air;

• 20s duration;

• The number of consumable starts can reach more than 500 times (ISO9013 Range 2).

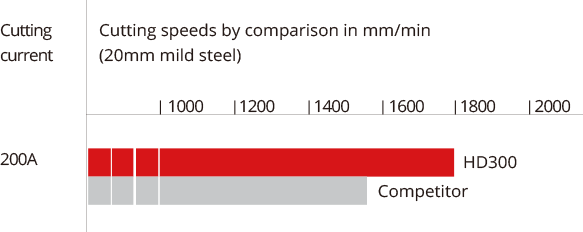

Fast Cutting Speed

The cutting speed of dross free can reach 1600mm/min for 20mm mild steel.

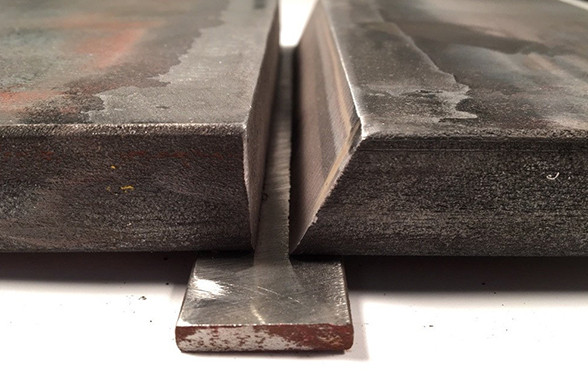

Bevel Cutting Technology

Bevel Cutting Technology is a performance application for mild steel. Factory tested and easily implemented, it takes the guesswork out of the plasma bevel-cutting process. With Bevel Cutting Technology, setups for new jobs are quick and results are accurate and consistent.

• 1 iteration

• Using True Bevel

• Acceptable part and ready to start production

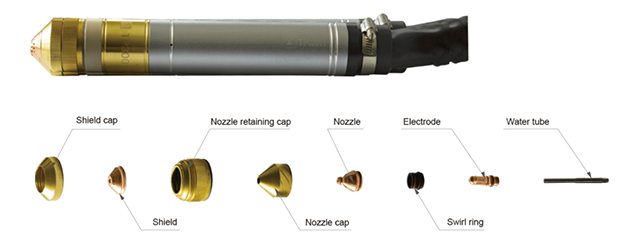

Refined Torch System

• Double air system torch

• Nozzle cooling for increased electrode life and reduced operating costs

• Work with TOPWELL high voltage power source to shift the cutting limitation

VIDEO

SPECIFICATIONS

Machines

|

Product Name

|

HD200W

|

|

Cut angle(ISO 9013 range*)

|

2

|

|

Weldability

|

Ready to weld

|

|

Plasma gas

|

Air

|

Shield gas | Air; Water Spray |

Product Weights & Dimensions

|

Dimensions(L*W*H)

|

960*420*1100mm

|

|

Net Weight

|

156KG

|

Basic Specification

|

Input Voltage

|

380V/400V, 3PH, 50/60Hz

|

|

Input Power

|

50KVA

|

|

Rated output voltage

|

50~200VDC

|

|

Rated Output(40℃) 100%

|

200A

|

Open circuit voltage (OCV) | 430VDC |

* ISO 9013 is a standard that defines cut quality of thermally cut parts. The lower the range (range 1 is the lowest), the smaller the angle on the cut face. Cut angle in range 4 is better than in range 5.

YOU MAY ALSO NEED

TP300 Consumable Kit

Related Products

ANY COMMENTS? YOU ARE WELCOME TO LEAVE MESSAGE TO US!

- Tel

- *Title

- *Content

Review

- Loading...