Topwell High Speed MIG 500 Pulse MIG MAG MMA welder Heavy Duty Welding Machine ProMIG-500SYN DPulse

Topwell High Speed MIG 500 Pulse MIG MAG MMA welder Heavy Duty Welding Machine ProMIG-500SYN DPulse

-

PROMIG-500SYN DPulse

Ultra High Deposition Rate, Ultra High Welding Performance

-

Application:

Metal fabrication workshops

Shipyards and offshore industry

Chemical and process industry

Steel structure workshops -

Processes:

CO₂ /MAG /MIG

FCAW

MMA(Stick) -

Input Power: 380V, 3-Phase

Rated Output at 40°C (104°F):

500A at 39V @60% Duty Cycle

Weight: 96KG

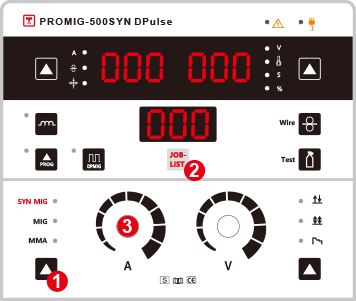

SIMPLE OPERATION

3 Steps to achieve weld perfection

1. Select operation mode

2. Select Job-list No.

3. Adjust welding current

(always the perfect setting by the synergic function

using the material thickness)

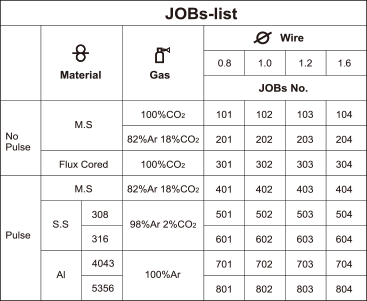

Synergy control with job-list

The Job-lists display is easily and intuitively controlled through its graphical user interface.We assembled the perfect welding curve in every Job-No. for highly efficient multi-process welding of carbon steels and stainless steel and aluminum alloys. Operation is easier than ever before.

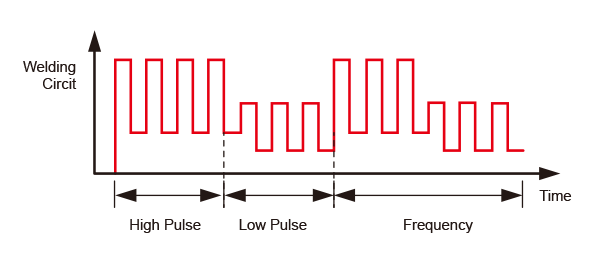

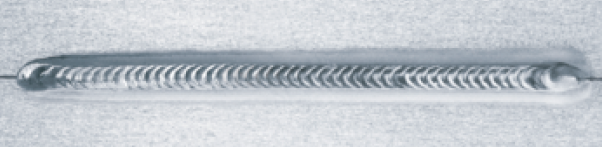

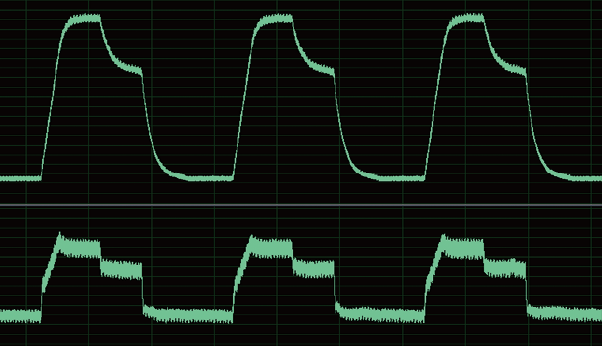

HIGH SPEED DOUBLE PULSE MIG PROCESS

Compared with the traditional DoublePulse, High Speed Double Pulse process can increase the welding speed by about 25%. Welding quality is comparable to TIG process.

No need to swing, You can easily get a cosmetically pleasing weld seam, with significantly lower and more controller heat input into the workpiece. It results in much lower distortion and less rework, very suitable for welding the thin Aluminum or S.S sheets.

By High-Speed Double Pulse process, the heat input of arc is alternating, effectively reducing the heat input of base metal. It reduces the occurrence of welding defects such as crack.

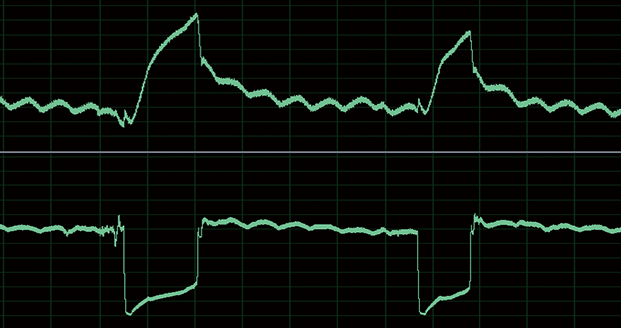

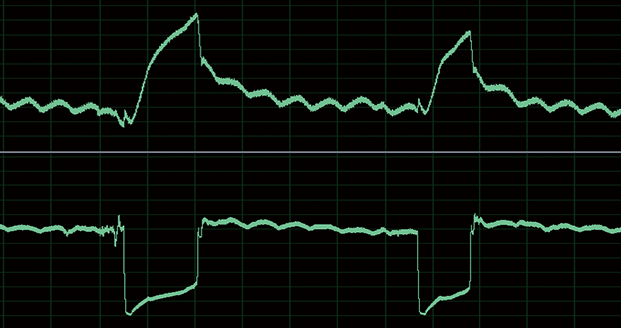

ULTRA LOW-SPATTER IN CO₂ WELDING

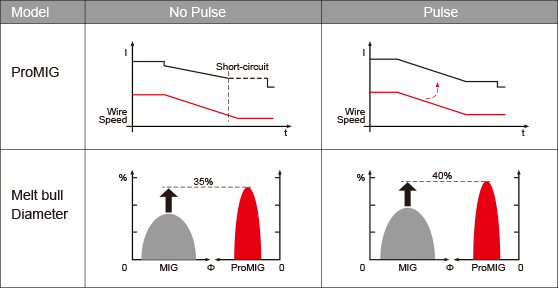

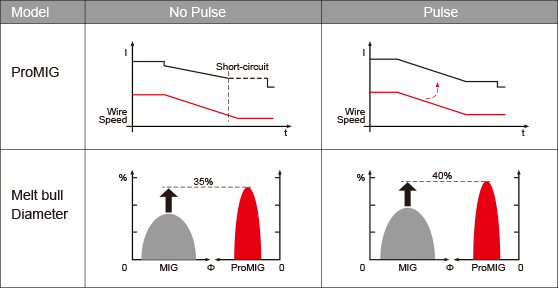

• Initial Short Control reduces the amperage immediately after the wire shorts which stabilizes the short, minimizing the spatter caused by wire chattering.

• Neck Control detects the moment droplet detachment begins to neck then quickly reduces the amperage before short releases. Releasing the short at a lower amperage reduces fuse effect energy.

• Stable Transfer Control increased amperage directly after the short release. Adding amperage quickly burns the wire to prevent secondary shorting. The faster burn off creates the droplet faster and reduces total arc time which increases the frequency and provides a crisp and clean arc. For CO₂ process that suppresses weld pool vibration preventing secondary shorting.

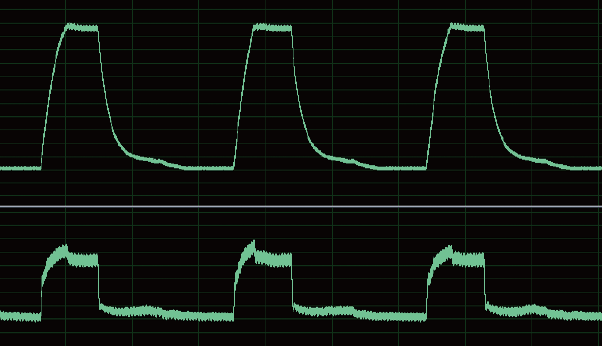

EQUIPPED WITH TOPWELL’S HIGH SPEED-PULSE PROCESS

Best for high quality and high speed welding of medium and thick plates. In the matter of welding speed, everything starts with the wire. each pulse must melt the largest amount of material. while only on droplet per pulse is transferred for the standard pulse process, high Speed-pulse prcoess achieves an almost constantly flowing metal transfer into the workpiece.

Benefits:

·Higher productivity due to faster we;ding speeds, up to 30% quicker.

·Lower heat input for:

-better weld quality and integrity

-minimal(angular)distortion

-minimal dilution of the filler wire alloying elements

·Better and deeper penetration depth

VERTICAL-UP WELDING AS EASY AND FAST AS NEVER BEFORE

The HSP optimised for fillet welds (FW) completed using PF welding (in vertical up position); can also be used to great benefit in other weld positions. For Topwell ProMIG Series, HSP is approx 70 % faster, an enormous progress for everyone welding a vertical seam. A whole new level! No need to swing! No undercuts or other defects! The speed of PF welding by HSP is twice that of the traditional pulse welding.

IMPROVED OPERATION PROCESS & CONTROLS

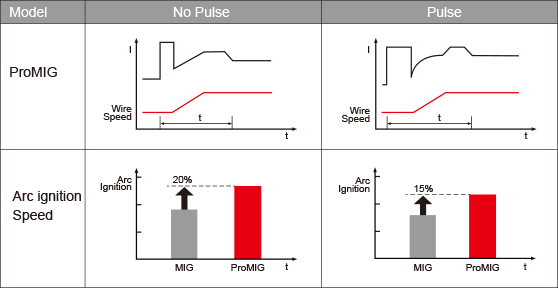

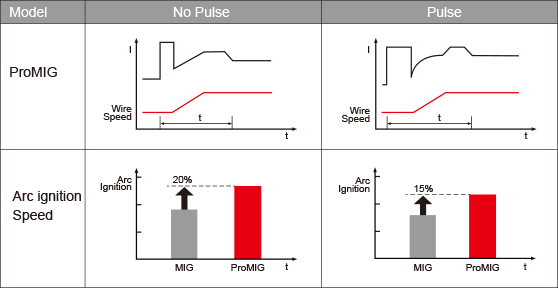

Initial Arc control

We control the arc energy by welding waveform, so the success rate of arc ignition can be improved and quickly establish a molten pool.

Burn Back control

Adjustable time delay between turning off the arc and the wire feed to prevent wire sticking to the puddle.

Burn Back control

Adjustable time delay between turning off the arc and the wire feed to prevent wire sticking to the puddle.

Initial Arc control

We control the arc energy by welding waveform, so the success rate of arc ignition can be improved and quickly establish a molten pool.

IMPROVED OPERATION PROCESS & CONTROLS

-

-

Item No PROMIG-500SYN DPulse Mains voltage(V) 3PH~380V ±15%(50/60Hz) Max.Load Power Capacity 24.08KVA Output Property CV Open Circuit Voltage 70V Voltage Synergy/NO Welding range(A) DC 10~500 Process CO₂/MAG/ MIG/FCAW-G 60% 30A/15.5V~500A/39V 100% 30A/15.5V~350A/31.5V Power Factor 0.92 Efficiency 85% Wire feed unit 4 rollers Wire feed speed range 0~25m/min Wire Spool Capacity 300mm (15kg) Weldable wires steel(mm) 0.6~1.6 mm Weldable wires Aluminum(mm) 1.0~1.6 mm Flux Cored 0.8~1.6mm Standard EN 60974-1 Protection class(EN 60529) IP23S Insulation class F Designation CE,ROHS Dimension 960x420x1400mm Weight 80KG Water-cooling Unit: WC-150 Operating Voltage 230V 50/60Hz Rated Power 260W Cooling Power 1.5KW(1L/MIN) Maximum Pressure 0.3MPA/60HZ Recommended Cooling Liquid 20%~40% ethanol/water Tank Volume 6.5L - For Standard accessories

MIG torch:MIG-24

Earth clamp

For Optional accessories

BINZEL MB EVO PRO 501D

Argon gas regular

or CO₂ gas regular with heater

-

-

Q:Are you a factory or a trading company?

A: We are factory with more than 10 years manufacturing experience and we provide perfect OEM and after-sale service.

Q:How can I pay my order?

A: We accept T/T, Western Union, Alibaba Trade Assurance payments. For those orders less than 1000USD, we accept PayPal to pay.

Q:How about your warranty?

A: We offer 3-year product life guarantee ,and a generous 1 year warranty on al purchases that begins with the bill of lading.

Q: Do you have a CE certificate?

A: For every model of machine, it has a CE certificate.

Q:How can I get the quotation?

A: We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price,please send the message on trade management or call us directly

- Tel

- *Title

- *Content

- Loading...