synergic,Pulse MIG Welder MIG-350HD/500HD

/FEATURES

Quick Specs

- Industrial Application:

- Metal fabrication workshops

- Chemical and process industry

- Shipyards and offshore industry

- Steel structure workshops

- Processes:

- MIG

- MIG (GMAW-P) Pulsed

- Stick (SMAW)

- Input Power: 350HD: 3PH ~ 400V ±15%

- 500HD: 3PH ~ 400V ±15%

- Amperage Range: 350HD: 10-350A/500HD: 10-500A

- Rated Output at 40℃ (104℉):

- 350HD: 350A at 31.5V @60% Duty Cycle

- 500HD: 500A at 39V @60% Duty Cycle

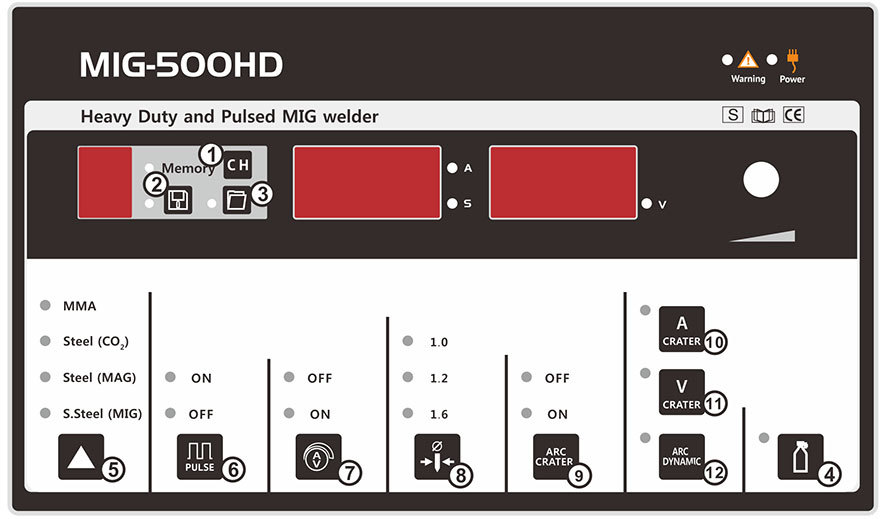

General View of Control Panel

1. SELECT the Memory channel

2. OPEN the parameter of selected memory channel

3. STORE the setting to Memory channel

4. Push to Check Gas

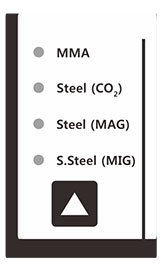

5. Welding Process

MMA,

MAG(CO2)for Carbon steels

MAG(CO2/Ar) for Carbon steels

MIG (Argon) for Stainless steels6.Pulse MIG:ON/OFF

7.Synergic function:ON/OFF

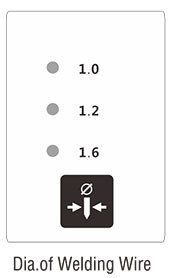

8.Synergic setting (select wire diameter)

9.Arc Crater: ON/OFF

10.Select to adjust the Arc Crater Current

11.Select to adjust the Arc Crater Voltage 12.Arc Dynamic controls

Synergic MIG

Synergic pulsed welding

mode offers the simplicity

of single-knob control.The

machine will select the

correct pulse power based

on the wire feed speed

(WFS) set by the operator.

Select the base materials

and shield gas

MAG(CO2)for Carbon steels

MAG(CO2/Ar) for Carbon steels

MIG (Argon) for Stainless steels

Classical MIG/MAG

In classic mode, MIG / MAG welding is carried out in inert gas with automatic wire feed.With this mode, a high welding speed and excellent quality are offered without any extra costs in the processing offerrous metals, as well as various steels.

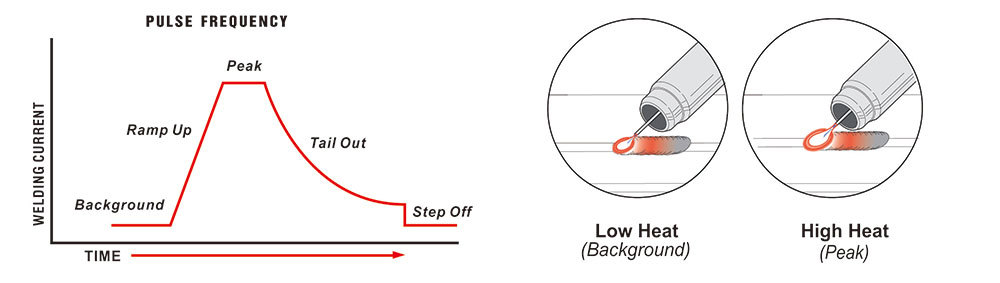

Pulse MIG

PMIG enables getting high quality stainless steel products. In this mode, on the main current will be superimposed transient current pulses and providing a rapid melting of the wire. As a result, the metal has no nodules. The MIG pulse also carries out a crushing crystals melt zone and form a tight seam quality. In addition, all the impurities are blown out of the weld pool. Adjustable heat input improves the quality of welding thin-walled metals. This prevents overheating of the aluminum to ensure the metal does not warp. It also decreases spatters and improves geometry and appearance of the weld joint. PMIG is indispensable for welding stainless steel, aluminum and other nonferrous metals which are sensitive to heat input.

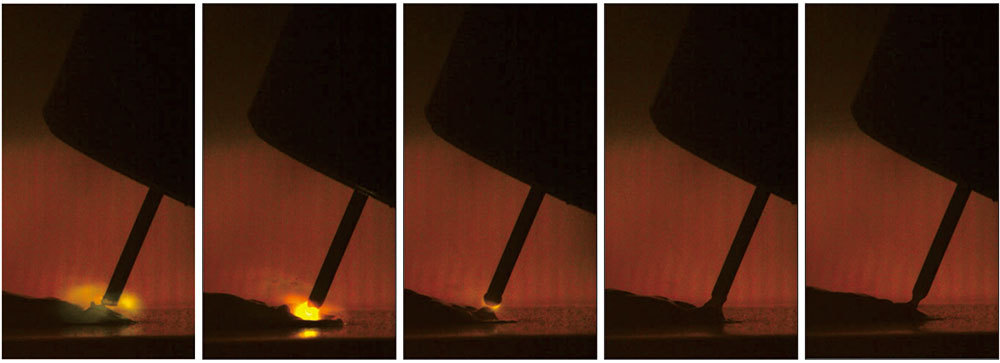

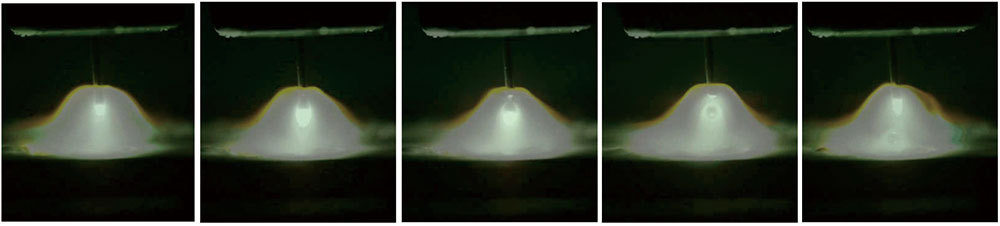

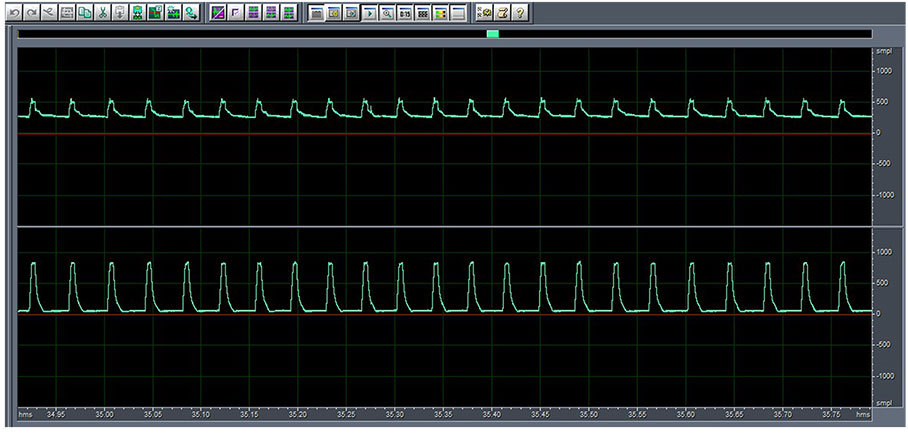

The advantage of Wave-form Control System

Fe,Pulsed

Fe,no Pulsed

The latest technology of Waveform Control System with pulsed MIG control mode, can perfectly control the output of

welding power and get the precision Arc performance. The wire melting droplet transfer cycle is very clear, the welding

beam is very clean and very few spatters during welding.

/SPECIFICATIONS

Technical specifications

Item No MIG-350HD MIG-500HD Rated Input Voltage 3PH ~ 400V ±15% 3PH ~ 400V ±15% Max. Load Power Capacity 15.26KVA 26.99KVA Rated Duty Cycle(40oC) 60% MIG: 350A/31.5V MIG: 500A/39V MMA: 350A/34V MMA: 500A/40V 100% MIG: 300A/29V MIG: 350A/31.5V MMA:300A/32V MMA:350A/34V Welding Current/Voltage Range MIG: 10A/14.5V~350A/31.5V MIG: 10A/14.5V~500A/39V MMA:10A/20.4V~350A/34V MMA:10A/20.4V~500A/40V Open Circuit Voltage 70V~80V 70V~80V Power Factor 0.85 0.85 Efficiency 85% 85% Pre-Gas Time Preset Preset Flow-Gas Time Preset Preset Wire-feed Mechanism 4 Rollers 4 Rollers Wire-feed Speed Range 0~25m/ min 0~25m/ min Wire Spool Capacity 300mm (15kg) 300mm (15kg) Filler Wires Ø (mm) Fe, Ss: 0.6~1.6 mm 0.6~1.6 mm FLUX CORED: 0.8~2.0 mm 0.8~1.6 mm Al: 1.0~2.4 mm 1.0~1.6 mm Dimension 960x420x1400mm 960x420x1400mm Weight 85KG 85KG

/ACCESSORIES

For Standard accessories MIG torch: MIG-501D

MIG torch: MIG-501D Earth clampFor Optional accessories

Earth clampFor Optional accessories Argon gas regular

Argon gas regular CO2 gas regular with heater

CO2 gas regular with heater Trolley:WT-150

Trolley:WT-150/RESOURCES

/DOCUMENTS

- Tel

- *Title

- *Content

- Loading...