PROTIG-200Di/250Di

/FEATURES

Quick Specs

- Application:

- Installation and set-up

- Repair and maintenance

- Thin sheet metal fabrication workshops

- Chemical and process industry

- Processes:

- DC TIG (GTAW)

- Stick (SMAW)

- Input Power: 200Di: 230V, 1-Phase

- 250Di: 230V, 1-Phase

- Amperage Range:200Di: 3-200A

- 250Di: 3-250A

- Rated Output at 40℃ (104℉):

- 200Di: 200A at 18V @60% Duty Cycle

- 250Di: 250A at 20V @60% Duty Cycle

- Weight:15kg

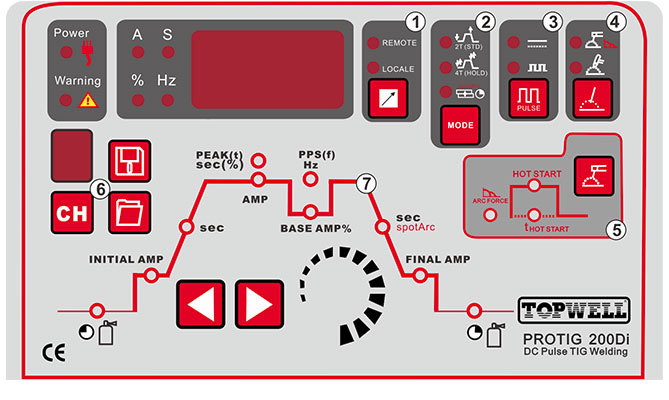

General View of Control Panel

1.Remote:used for foot pedal or Remote torch.

Local:adjusted Currents bu face panel

2.2T/4T holding mode or

Spot Welding mode selection.

3.Pulse ON/OFF selection.4.Process selsction.

5.ARC FORCE/HOT START

6.Memory with capacity of 10 sets parameters.

7.Function Sequence

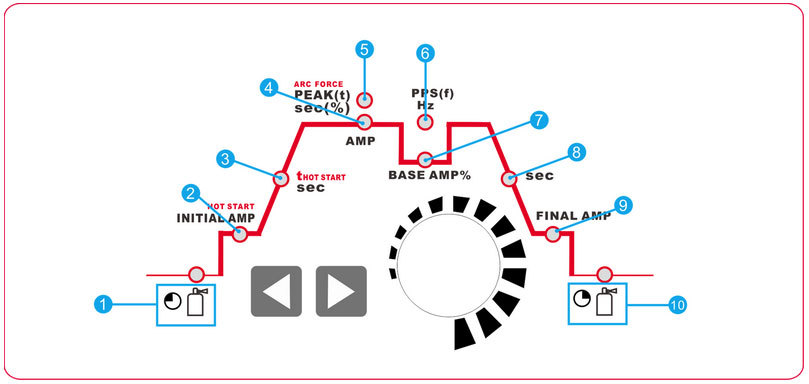

General View of Control Panel(Continued)

1.Gas pre-flow time(TIG)

Absolute setting range 0.1s to 5.0s (0.1s increments).

2.Ignition current(TIG)

Percentage of the main current.

Setting range 1% to 100%(1% increments).3.Up-slope time(TIG)

Setting ranges:0.00s to 20.0s(0.1s increments).

The up-slope time can be set separately

for non-latched and latched.4.Main current(TIG)/pulse cuttent

I min to max(1 A increments)

Main cuttent(MMA)

I min to I max(1 A increments)5.Pulse time

Pulse time setting range:0.01s to 9.99s(0.01s increments)

TIG pulses

The pulse time applies to

the main cuttent phase(AMP) for pulses.6.Pulse break time

Pulse break setting range:0.01s to 9.99s

(0.01s increments).TIG pulses

The pulse break time applies to the secondary

current phase(AMP%).7.Secondary current(TIG)/pulse pulse pause current

Setting range 1% to 100% (1% increments).

Percentage of the main current.8.Down-slope time(TIG)

0.00s to 20.0s (0.1s increments).

The down-slope time can be set separately

for non-latched and latched.9.End-crater current(TIG)

Setting range 1% to 100%(1% increments).

Percentage of the main current.10.Gas post-flow time(TIG)

Setting ranges:0.1s to 20.0s(0.1s increments).

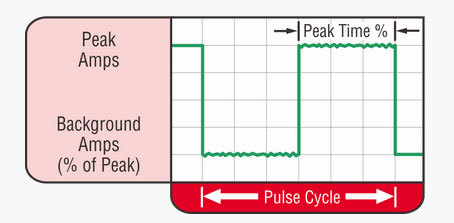

DC TIG-Pulse

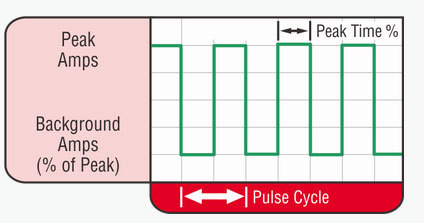

High Speed DC TIG-Pulse Controls

• PPS Pulses per second (Hz):DC = 0.1 – 5,000 PPS

• % ON – % Peak Time:5 - 95% (Controls the amount of time during each pulse cycle at the PEAK amperage.)

• Background Amps:5 – 99% (Sets the low-pulse amperage value as a % of the Peak Amps.)CONVENTIONAL PULSED TIG

HIGH SPEED PULSED TIG

Typically from 1 to 10 PPS. Provides a heating and

cooling effecton the weld puddle and can reduce

distortion by lowering the average amperage. This

heating and cooling effect also produces adistinct

ripple pattern in the weld bead. The relationship

between pulse frequency and travel speed determines

the distance between the ripples. Slow pulsing can

also be coordinated with filler metal addition and

can increase overall control of the weld puddle.

In excess of 40 PPS, Pulsed TIG becomes more

audible than visible—causing increased puddle

agitation for a better as-welded microstructure.Pulsing the weld current at high speeds — between

a high Peak and a low Background amperage —

can also constrict and focus the arc.This results in

maximum arc stability, increased penetration and

increased travel speeds(Common Range:100–500PPS).The Arc-Sharpening effects of high speed

pulsing are expanded to new dimensions. The ability

to pulse at 5,000 PPS further enhances arc stability

and concentration potential — which is are required.

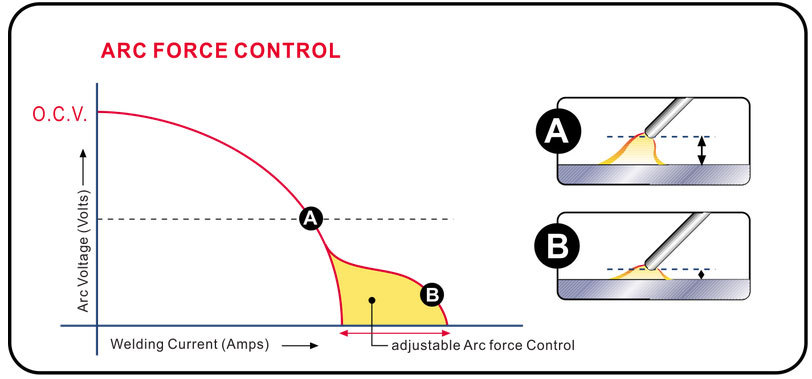

Arcforce correction (welding characteristics)

During the welding process, arcforce prevents the electrode sticking in the weld pool with increases in current.

This makes it easier to weld large-drop melting electrode types at low current strengths with a short arc in particular./SPECIFICATIONS

Technical specifications

Item No PROTIG-200Di PROTIG-250Di Rated Input Voltage 1PH ~ 230V ±15% 1PH ~ 230V ±15% Max. Load Power Capacity TIG: 5.62KVA TIG: 7.81KVA MMA: 6.60KVA MMA: 5.63KVA Rated Duty Cycle(40℃) 60% TIG: 200A/18V TIG: 250A/20V MMA: 160A/26.4V MMA: 200A/18V 100% TIG: 160A/16.4V TIG: 200A/18V MMA: 130A/25.2V MMA: 160A/26.4V Welding Current/Voltage Range TIG: 3A/10.1V~200A/18V TIG: 3A/10.1V~250A/20V MMA: 20A/20.8V~160A/26.4V MMA: 20A/20.8V~200A/28V Open Circuit Voltage 70V~80V 70V~80V Power Factor 0.8 0.8 Efficiency 80% 80% TIG Pulse Frequency 0.2Hz~200Hz 0.2Hz~200Hz Pulse Width (Ratio) 1~100% 1~100% Arc-starting Current 5A~200A 5A~250A Crater-filling Current 5A~200A 5A~250A Current Up-slope Time 0.1S~15S 0.1S~15S Current Down-slop Time 0.1S~15S 0.1S~15S Pre-Gas Time 0.1S~15S 0.1S~15S Flow-Gas Time 0.1S~15S 0.1S~15S Spot Arc Time 0.1S~10S 0.1S~10S MMA Arc Force 10A~160A 10A~200A Hot Start Time 0.1~3S 0.1~3S Hot Start Current 10A~160A 10A~200A Dimension (LxWxH) 410X190X305mm 410X190X305mm Weight (KG) 15 KG 15 KG

/ACCESSORIES

For Standard accessoriesFor Optional accessoriesVIDEO

It is a lightweight and compact designed dc tig welding machine,

including a 250amps power source as same as our Protig-250Di.

/DOCUMENTS

- Tel

- *Title

- *Content

- Loading...