Multi MIG-200Di/200MV

/FEATURES

Quick Specs

- Light Industrial Application:

- Thin sheet metal fabrication

- Car repairs

- Agriculture

- Installation and set-up

- Repair and maintenance

- Processes:

- MIG (GMAW)

- MIG(GTAW) Lift-Arc

- Stick (SMAW)

- Input Power: 115/230V, 1-Phase

- Amperage Range: 20-200A

- Rated Output at 40℃ (104℉):

- 200A at 28V @35% Duty Cycle

- Weight:20kg

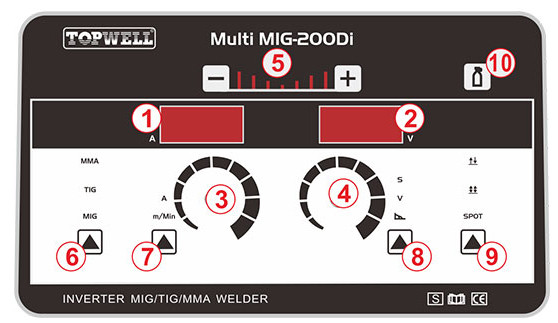

General View of Control Panel

1.Display, left

Welding current

2.Display, right

Welding voltage, Times(S,0.1s)

3.Welding parameter setting, rotary dial

Adjustment of the welding current or Wire feed speed

Press to Adjust the Arc Crater Curren.

4.Rotary dial, welding voltage

Adjustment of the welding voltage/ Times and Arcforce

Press the Arc Crater Voltage.

5.button, throttling effect (arc dynamics)

"-"Arc is softer and wider

"+"Arc is harder and more narrow

6.Button, welding process

MMA welding

MIG/MAG welding

TIG welding7.Button, Parameter selection

Welding current

Wire feed speed

8.Button, Parameter selection (up)

Welding times:S, 0.1s

Welding voltage

Arcforce :To adjust the welding parameters to

the electrode type used. Infinite setting

from rutile (soft arc) to cellulose (hard arc)

electrode types.

9.Torch holding mode

2T holding mode

4T holding mode

10.Gas test button)

Gas test: For setting the shielding gas quantity

The advantage of Wave-form Control System

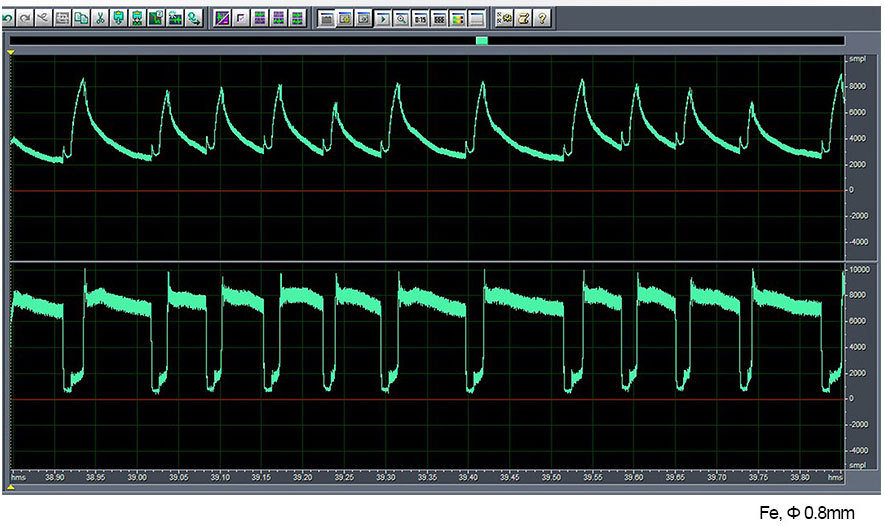

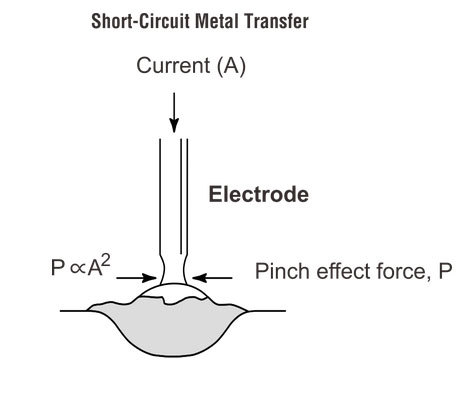

Featured Wave-form control system:

Perfect waveform of volts/amps during Short Circuits and Arc Burning process (very smooth welding drop transfer).

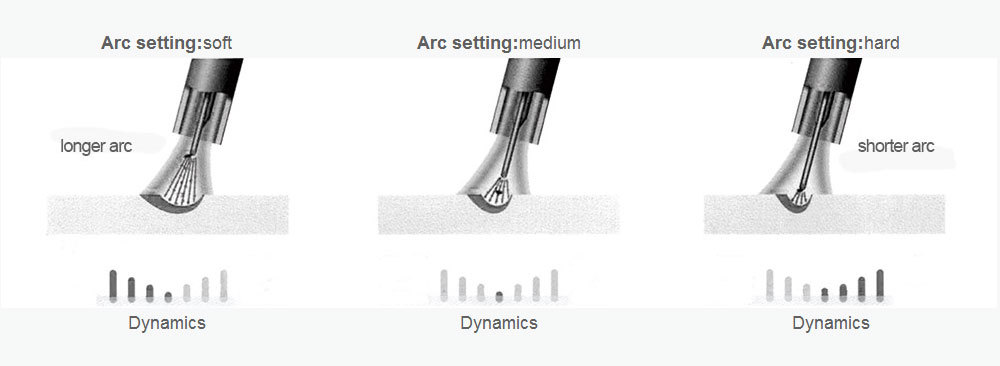

Dynamic Control Dynamic control with a push of a button

You know how it is from experience. Every transformer system has its own unique characteristics.One system

produces a slightly softer arc,while the next generates a slightly harder arc.More importantly,every welder has his

own preference in terms of what he considers to be the perfect arc:softer and longer,shorter and harder or

somewhere in between.This calls for a level of distinction that a transformer systems simply cannot realise. Our system

allows you to individually adjust the dynamics of the arc to suit the work and welding position at hand and will find

the simplest and fastest arc setting that is most suitable in each case.The rest of the job is carried out by the

intelligent arc control technology incorporated into the background to achieve a perfect weld seam every time.

Waveform control system for

precision Arc performance,

Portable but heavy duty.

We designed and built the Multi MIG-200Di/200MV

based on the waveform control system from the

standard MIG welding process. From the full cycle

of the wire melting drop transfer between the short

circuits and arc burning,the Multi MIG-200Di/200MV

can perfectly control the output of welding power.

With the features of powerful peak current and

Dynamic control system,the Multi MIG-200Di/200MV

is portable but very heavy duty.

/SPECIFICATIONS

Technical specifications

Item No MIG-200Di MIG-200MV Rated Input Voltage 1PH ~ 230V ±15% 1PH ~ 115V/230V ±15% Max. Load Power Capacity 8.75KVA 6.06KVA Rated Duty Cycle(40℃) 35% MIG: 200A/24V MIG: 200A/24V MMA: 200A/28V MMA: 200A/28V TIG: 200A/18V TIG: 200A/18V 100% MIG: 160A/22V MIG: 160A/22V MMA: 160A/26.4V MMA: 160A/26.4V TIG: 160A/16.4V TIG: 160A/16.4V Welding Current/Voltage Range MIG: 10A/14.5V ~200A/24V MIG: 10A/14.5V ~200A/24V MMA: 20A/20.8V~200A/28V MMA: 20A/20.8V~200A/28V TIG: 5A/10.2V~200A/18V TIG: 5A/10.2V~200A/18V Open Circuit Voltage 70-80V 70-80V Power Factor 0.8 0.8 Efficiency 80% 80% Pre-Gas Time preset preset Flow-Gas Time preset preset Wire-feed Mechanism 2 Rollers 2 Rollers Wire-feed Speed Range 2-18 m/min 1-13 m/min Wire Spool Capacity 200mm (5kg) 200mm (5kg) Filler Wires (mm) Fe solid wire: 0.6~1.0 mm 0.6~1.0 mm Dimension 490x230x385mm 490x230x385mm Weight 20KG 20KG /ACCESSORIES

For Standard accessoriesFor Optional accessories/RESOURCES

/DOCUMENTS

- Tel

- *Title

- *Content

- Loading...