Home / All

News

- AC wave shape options and Benefits on ALUTIG-200PThe total solution of TIG welding.Oct 28,2016

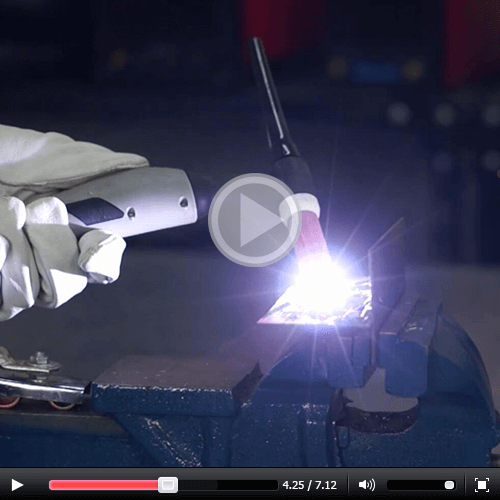

This video is about four wave forms option and benefits, the model is TOPWELL ALUTIG-200P.

For more details, please visit our website at:

www.topwellwelders.com

Like us on facebook,linkedin, twitter, instragram to get more infos! - What is Pulsed MIG?In simple terms, pulsed MIG is a non-contact transfer method between the electrode and the weld puddle. This means that at no time does the electrode ever touch the puddle.Oct 27,2016

- Synergic Setting on MIG WeldingOct 14,2016

- Some points about Footpedal FX-390BSep 29,2016

- HF START VS. LIFT START TIG VS. SCRATCH STARTIf you are left “scratching” your head about the differences in the different start methods of TIG, you are not alone. Many experienced users get the facts wrong when it comes to the 3 basic ways you can start a TIG arc.Sep 29,2016

- CO₂ arc welding different droplet transfer formThe gas metal arc welding (GMAW) process uses four basic modes to transfer metal from the electrode to the workpiece. Each mode of transfer depends on the welding process, the welding power supply, and the consumable, and each has its own distinct characteristics and applications.Sep 26,2016

- Pulsed TIG ControlsThe Pulsed TIG function switches the amperage from a high(peak) to a low(background) at a set rate(PPS). Pulsing can reduce heat input by lowering the average amperage, increasing control of the weld puddle, penetration and distortion. The following parameters can be adjusted for desired results:Sep 7,2016

- AC waveshape options and BenefitsAug 31,2016

- TIPS FOR BETTER GRAM RESULTSAug 29,2016

- The First Chinese City To Host G20 summitG20 summit will be held in Hangzhou during 1st to 7th on Sep. For some security reasons, Express company like DHL and TNT in HangZhou will be off on those days.Aug 26,2016

- Spot WeldingAug 26,2016

- Creating a safe welding environmentAug 25,2016

- What's Pulse MIG & Double Pulse MIG?Aug 23,2016

- About tig welding aluminum gasAug 18,2016

- TOPWELL PILOT ARC PLASMA CUTTING MACHINE CUT-70H Non-HF3 phase 380V Professional-grade plasma metal cutting machine(3 phase 400V±15%).Aug 17,2016

- TIG welding filler wire and Mig welding wireTIG welding filler wire and Mig welding wire from a spool are essentially the same composition except that mig welding wire often contains more silicon and that can actually be a good thing for TIG welding steel.Aug 17,2016

- TOPWELL PLASMA CUTTING MACHINE CUT-40DI&CUT-70HHigh quality plasma cutting machine!Aug 17,2016

Low operating cost!

learn more at:http://www.topwellwelders.com/pid17944476/CUT-70H.htm

Find more at: www.topwellwelders.com!

Like us at: https://www.facebook.com/topwellwelders/ - Use the correct wire type for the base metal being welded.Use stainless steel wires for stainless steel, aluminum wires for aluminum, and steel wires for steel and nickel alloy rods for nickel alloys. (cast iron is welded with nickel wire but that’s a story for another day)Aug 16,2016

- Hands in tig welding operationIf you have problems feeling the wire with a glove, Try some mechanics gloves or really soft and thin tig gloves like Topwell BL-1005 skin tig gloves or even some woven cotton gloves...Aug 12,2016

- For TIG welding, the metal needs to be cleanTIG welding is not nearly as forgiving as Mig or stick when it comes to dirty metal. For TIG welding, the metal needs to be clean; no rust, scale, paint, etc.Aug 11,2016

- Argon is not the only shielding gas used for TIG weldingShielding gasses for TIG welding Argon is not the only shielding gas used for TIG welding…Aug 10,2016

- What is the Synergic ?With the continuous progress of science and technology,Most industrial mechanization industry also tends to one-button operation.For example, the welding industry.Aug 10,2016

- TIG Torch angle had better keep 10 degrees or lessIdeally, torch angle should only be around 10 degrees or less. Too much torch angle will deflect the heat and melt the rod before you ever get it into the puddle.Aug 9,2016

- Don’t use too much torch gas when welding aluminum on ACDon’t use too much torch gas when welding aluminum on AC. Aluminum takes a lot of amperage to weld.Aug 8,2016

- Tig welding tipsExtend the tungsten out of cup 1/4” to 5/16” when welding high amperage aluminum or heat will radiate from the cup to tungsten and reduce output, especially if the orifice is too small.Aug 5,2016

- How arc initiation works for plasma cuttingWhen it comes to plasma cutter start functions, you always get two answer:Aug 5,2016