Tips&Tricks

- Set the machine so that you are at welding amperage with the foot pedal depressed about 3/4 of the waySet the machine so that you are at welding amperage with the foot pedal depressed about 3/4 of the way.Aug 4,2016

- Put a vent hole in anything you weld that will be sealed up completelyPut a vent hole in anything you weld that will be sealed up completely or air will heat up and expand and blow away your shielding gas or even blow out at the end of the weld bead.Aug 3,2016

- Torch angle effects penetrationThe more vertical the torch is, the more arc is directed into the part. Think about it like this…Aug 2,2016

- Topwell Tips :How to prevent sugaring on stainless pipeIf you are welding stainless pipe with a purge and your weld is still sugaring, remember argon is heavier than air and flows like water.Aug 1,2016

- What are the best settings to tig welding aluminum on DCEN?Well there is always a bit of fudge factor because flowmeters are different, and machines are different …Jul 29,2016

- What are the limitations of tig welding aluminum on DCEN?Usually AC is better for these situations. also, if you have large gaps to fill AC is usually better.Jul 28,2016

- Exactly where and why would you want to tig weld aluminum on DC?Because helium carries so much more energy and heat than argon, aluminum can be puddled very quickly so a puddle can be made very quickly even on very thick aluminum.Jul 27,2016

- Tungsten profile has a substantial effect on bead shape, width, penetration" sideways scratches on your tungsten will also cause pandemonium and the end of the world as we know it."Jul 26,2016

- Top 10 mistakes - tig welding aluminumOn transformer tig welders, forgetting to set high frequency to continuous when tig welding aluminum …..Jul 25,2016

- Tungsten size should be selected mainly according to amperage AND polarityTungsten size should be selected mainly according to amperage AND polarity and not always dependent upon metal thickness.Jul 22,2016

- Topwell:Mig welding tips - Lucky of the Best Mig Welding Tips everKeep wire in a clean, dry place when not welding, Rusty wire will not help us now... will it?.Jul 21,2016

- Use gas lens style collet bodies and cups to weld stainless steelUse gas lens style collet bodies and cups to weld stainless steel. The screen in the gas lens allows far better gas coverage of your welds.Jul 21,2016

- The Topwell MIG welding tips are...MIG welding tip...Get a better Ground clamp. This is probably one of the most important mig welding tips ever!Jul 19,2016

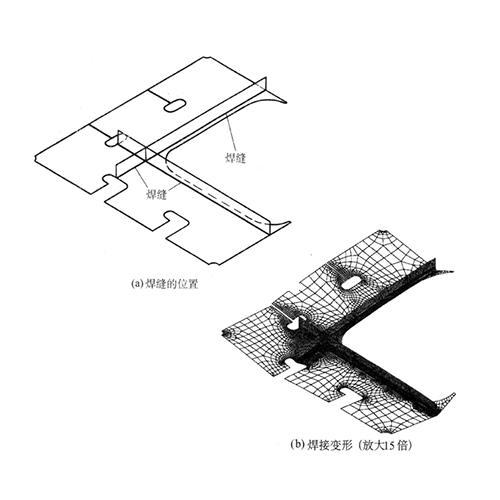

- Topwellwelders Tips:Avoiding Weld Distortion on Thin SheetWhat can we do to prevent the parts being distorted after welding?Jul 15,2016