Wire feeding system for MIG welding

As we all know that, MIG torch plays a very important roles in MIG welding, it can do wire feeding, gas feeding, and power switch. There are three method of wire feeding:Push, spool and push-pull.

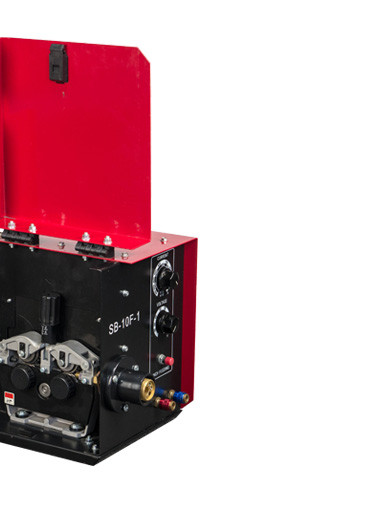

Push wire feeder:

|  |

Advantages and Benefits

Push systems are lower cost than other aluminum feeding methods since they only require one motor at the wire drive. In general, they work best for wire greater than 3/64". They also have the advantage of offering a compact gun to fit into tight spaces for providing better accessibility to the weld. Also, typical push wire feeders have the capacity to hold a common 12" outer diameter spool of aluminum electrode.

Limitations

A push system is typically not used for long gun lengths as the operator is likely to experience birdnesting or wire tangling. It also should not be used for smaller diameter wires.

Spool gun:

|  |

Advantages and Benefits

Spool guns are fairly simple to use and also have the benefit of being relatively inexpensive. For operators who don't want to be limited to welding within a short distance of the power source, a spool gun has the ability to reach as far as 50 ft. away.

Limitations

Because a spool gun is larger than a push gun, it can sometimes be difficult to get close access to the weld. Also, a spool gun can only hold a 1 pound spool of aluminum wire electrode, so changeovers are frequent. In addition, these small spools typically are not the most economical way to purchase wire.

Push pull torch:

|  |

Advantages and Benefits

This type of system offers the best of both worlds - the feeding performance of a spool gun with many of the advantages of a compact push system. A push-pull system provides the most uniform feeding and can hold larger spools of wire up to 8" in diameter (approximately 20 lbs). The gun can be taken long distances from the power source (up to 50 ft.). In addition, this system does not require the costly 1-lb. spools of the spool gun method and has a comfortable, ergonomic gun that fits into tighter places.

Limitations

Typically, the greatest disadvantage of a push-pull system is that it requires the most number of components and is the most expensive. But as we will explain later, this is not always the case as some of the latest technological innovations have addressed these concerns.