Synergic Setting on MIG Welding

Synergic Setting on MIG Welding

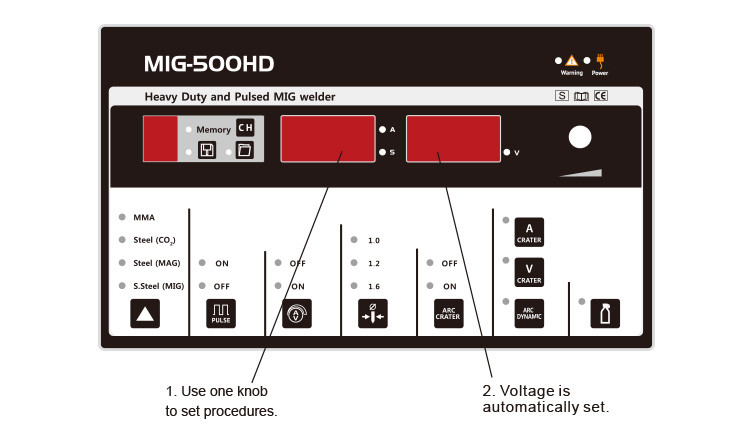

As this MIG-500HD panel shows

Once select the material type, gas condition and the wire diameter you need with one knob on this panel, with synergic setting control, then you can start to get your welding job smoothly.

Synergic setting on Mig Welding: provides communication between power source, feeder and gun. As wire speed increases or decreases, the arc voltage also increases or decreases to maintain a constant welding arc.

The merits of synergic setting With this setting can make the machine easy to use, even for the beginning welder. One knob control permits the welder to select the wire feed speed, and then the voltage value automatically follows.