Pulsed TIG Controls

The Pulsed TIG function switches the amperage from a high(peak) to a low(background) at a set rate(PPS). Pulsing can reduce heat input by lowering the average amperage, increasing control of the weld puddle, penetration and distortion. The following parameters can be adjusted for desired results:

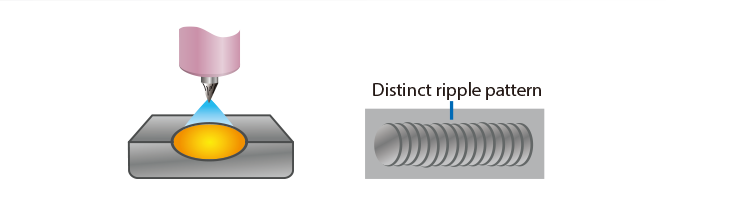

Low-Speed Pulse

1 to 10 pulses per second(PPS) will produce a distinct ripple pattern in the weld bead. Can be used to time filler addition, reduce distortion and improve control.

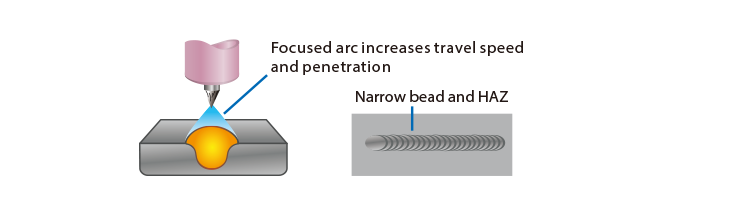

High-Speed Pulse

100 pulses per second(PPS) and higher helps to focus the arc or increased stability, penetration an d travel speed. Increased puddle agitation improves weld microstructure.