What's Pulse MIG & Double Pulse MIG?

DOUBLE PULSE

Double Pulse uses a sequence of varying pulse wave shapes to produce a TIG-like bead appearance and

excellent weld properties when MIG welding aluminum. Double Pulse controls arc length and heat input

together, making it easier to achieve good penetration.

excellent weld properties when MIG welding aluminum. Double Pulse controls arc length and heat input

together, making it easier to achieve good penetration.

PULSED MIG

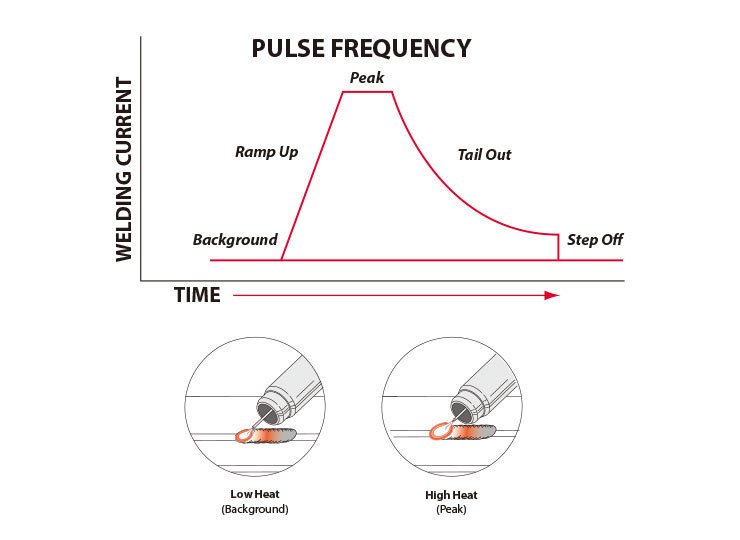

Pulsed MIG varies weld current between peak (high heat) and background (low heat) current to provide

better control of heat input, which minimizes warping and burnthrough on thin materials. Pulsed MIG

also enables flat, horizontal, vertical up, or overhead welding without a slag system. Optimized

GMAW-P waveforms are readily available to use on aluminum,carbon steel, high strength low alloy steel,

stainless steel, and nickel alloys.

better control of heat input, which minimizes warping and burnthrough on thin materials. Pulsed MIG

also enables flat, horizontal, vertical up, or overhead welding without a slag system. Optimized

GMAW-P waveforms are readily available to use on aluminum,carbon steel, high strength low alloy steel,

stainless steel, and nickel alloys.