Home / All / Plasma Cutting / All Product /

MAX200 High-Definition Plasma Cutting System with Extra Productivity

MAX200 High-Definition Plasma Cutting System with Extra Productivity

The HD-MAX plasma systems deliver high performance cut quality with Maximized cutting speed.

Detail Information

DETAILS

MAX200

Extra-Definition, Maximized productivity across a broad range of application needs, from very thin to heavier thicknesses.

Cutting Capacity

|

Mild Steel Cut Capacity

|

Thickness

|

|

Dross free*

|

25mm |

|

Production pierce

|

32mm

|

Maximum cutting capacity | 50mm |

Superior Cutting Performance

Optimized gas parameters are set and controlled by the software. With Oxygen/Air/N2/H35 plamsa gas, the MAX series plasma cutting system achieves impressive cut speeds, consistent cut quality and exceptional consumable life.

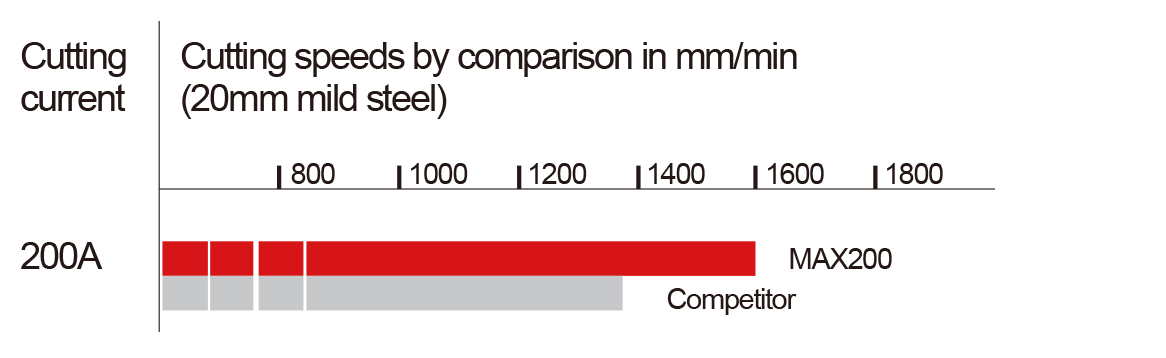

Maximized Productivity

· MAX Series provides faster cutting speed to maximize productivity.

· Engineered with 100% duty cycle for the most demanding production environments.

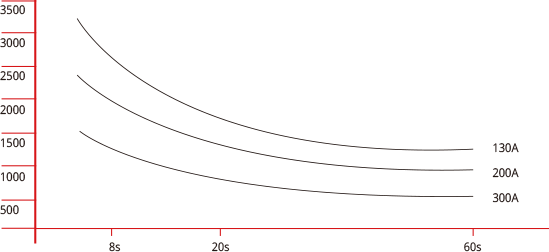

Long-life Consumables

The MAX200 system ramps current and gas flow up and down in a tightly controlled manner to reduce electrode and nozzle erosion.

Reducing electrode and nozzle erosion enables more consistent cut quality over a longer period of time, while providing a significant reduction in operating cost.

· Ignitions per cutting time in seconds

· 20 second duration

· MAX200: 810 times

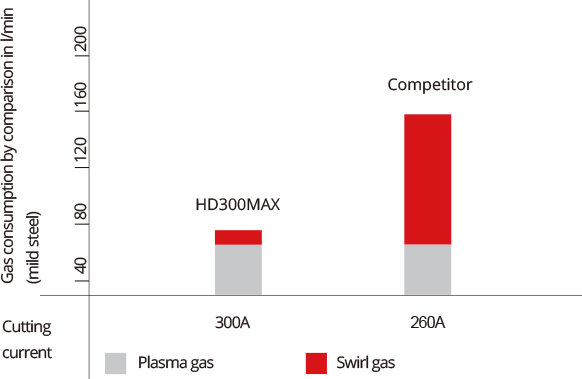

Efficient Gas Supply

The MAX200 plasma systems significantly increase the efficiency of gas and reduce the gas consumption.

· Cutting Current: 200A

· Gas consumption:

Plasma Gas: 60 l/min

Shielding Gas: 75 l/min

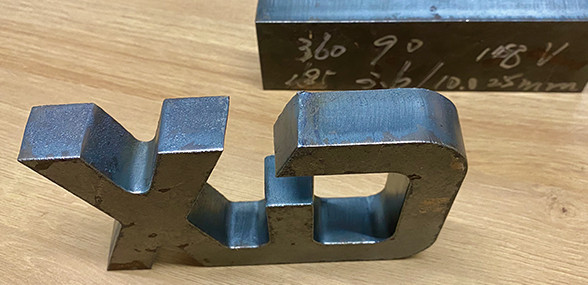

Bevel Cutting Technology

Bevel Cutting Technology is a performance application for mild steel. Factory tested and easily implemented, it takes the guesswork out of the plasma bevel-cutting process. With Bevel Cutting Technology, setups for new jobs are quick and results are accurate and consistent.

· 1 iteration

· Using True Bevel

· Acceptable part and ready to start production

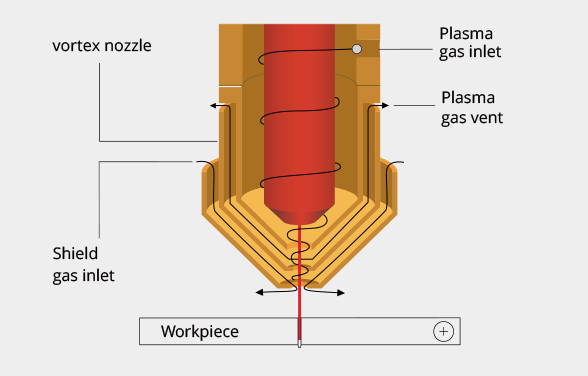

Refined Torch System

· Vented nozzle technology aligns and focuses the plasma arc.

· High Definition Cutting enables powerful precision cutting for superior quality and consistency on mild steel.

· High Definition delivers superior quality to thin stainless steel cutting.

VIDEO

SPECIFICATIONS

Machines

|

Product Name

|

MAX200

|

|

Cut angle(ISO 9013 range*)

|

2

|

|

Weldability

|

Ready to weld

|

|

Plasma Gas

|

O2; Air; N2; H35

|

Shield Gas | O2; Air; N2; |

Product Weights & Dimensions

|

Dimensions(L*W*H)

|

960*420*1100mm

|

|

Net Weight

|

165KG

|

Basic Specification

|

Input Voltage

|

380V/400V, 3PH, 50/60Hz

|

|

Input Power

|

50KVA

|

|

Rated Output Voltage

|

50~200VDC

|

|

Rated Output(40℃) 100%

|

200A

|

Open Circuit Voltage (OCV) | 430VDC |

* ISO 9013 is a standard that defines cut quality of thermally cut parts. The lower the range (range 1 is the lowest), the smaller the angle on the cut face. Cut angle in range 4 is better than in range 5.

YOU MAY ALSO NEED

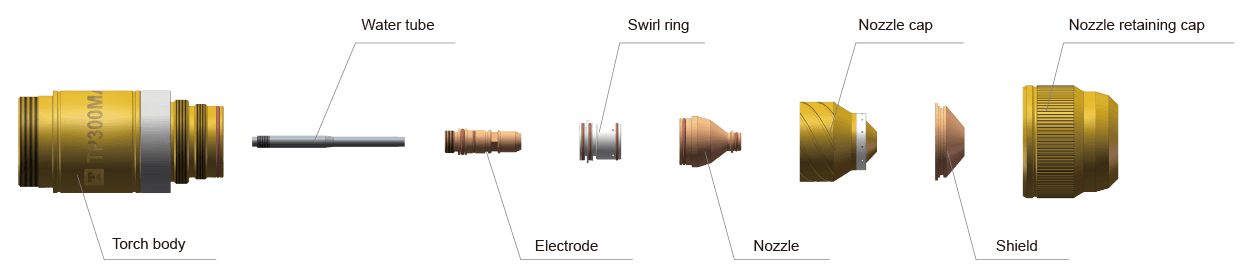

TP300MAX consumable Kit

TP260XD

TP260XD Consumable Kit

Gas Console (H35/N2)

Gas Console (Air/Air)

Related Products

ANY COMMENTS? YOU ARE WELCOME TO LEAVE MESSAGE TO US!

- Tel

- *Title

- *Content

Review

- Loading...