TOPWELL High definition Submerged Arc welding system SUBARC-1000XD/1250XD

TOPWELL High definition Submerged Arc welding system SUBARC-1000XD/1250XD

-

SubArc-1000XD/1250XD

TOPWELL High definition Submerged Arc welding system SUBARC-1000XD/1250XD

-

Processes:

MIG,

Flux-Cored,

Submerged Arc,

Gouging

-

Input Power:

340-460V/3-PH/50-60Hz -

Rated Output at 40℃ (104℉):

SubArc-1000XD: 1000A/50V/100%

SubArc-1250XD: 1250A/50V/100%

TOP Features

- Ability to preset the current;

- 100% duty cycle with a maximum output capacity;

- Reduced heat affected zone, minimized distortion and increased mechanical properties;

- Overloading, over current, loss of phase and short circuit protection ensure long-lasting performance;

- Use the mode switch to select the desired output characteristics for the process being used–CC and CV;

- Versatile power source is capable to MMA, MIG/MAG and Carbon Arc Gouging;

- Precise output control results in a stable arc;

- Modular parallel to enhance reliability;

- User-friendly operation panel.

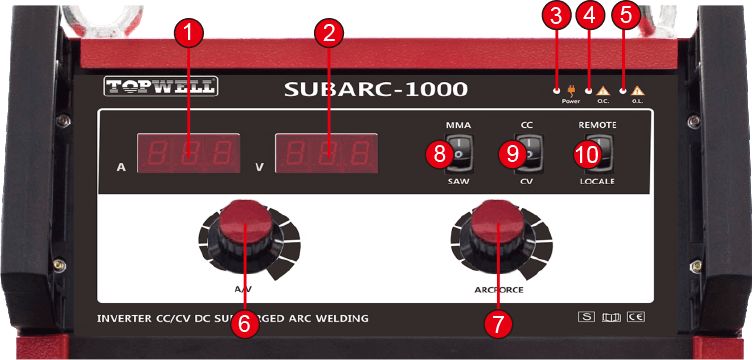

GENERAL VIEW OF CONTROL PANEL

1. Amperage Display

2. Volage Display

3. Power Indicator Light

4. Over Current Indicator Light

5. Over Loading Indicator Light

6. Amperage/Voltage Adjustment Control

7. Arcforce Knob

8. Function-MMA-or SAW

9. CC or CV Switch

10. Remote or Panel Switch

Submerged Arc Systems

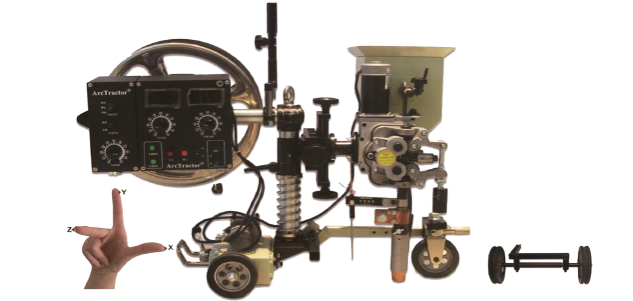

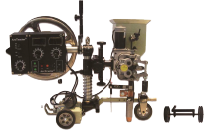

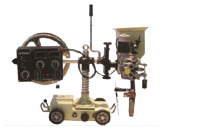

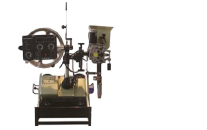

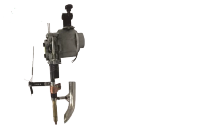

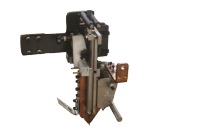

AT-1 SubArc Tractor

- Compact and efficient design allows for easy movement between work pieces;

- Self-propelled, 3-wheeled drive provides stable, accurate and constant operation;

- Arc Tractor Process Control with digital display, allows presetting and control of welding parameters;

- X-axis is the travel direction, 0.1-1.3mpm(3.9-51 IPM);

- +Y-axis (vertical) 0-70mm +± 100mm(Vertical head lift and slide);

- R y ±90°. Weld angle is up to 90°from vertical to either side;

- R z 45°. Angle forward or backwards by up to 45 degrees;

- R x 45°. Drag angle is up to 45°from vertical;

- Easily accommodates a 55-pound (25kg) wire reel for fewer wire changeovers.;

- Horizontal, vertical and rotary slides allow for quick adjustment of weld nozzle into various ;

- The rugged design ensures a long life span in harsh conditions;

- Manual clutch enables freewheeling movement of the tractor;

- Can upgrade to 4-wheel tractor.

More Tractors Available

For flat or fillet welding medium and thin plates

For various positions welding

For flat or fillet welding medium and thin plate, inside and outside circular

For Twin Wires Welding

For Twin Wires Welding

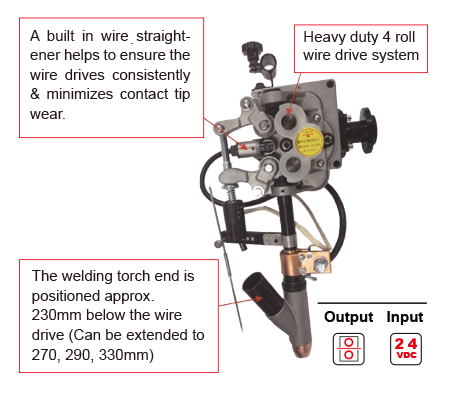

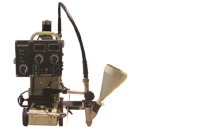

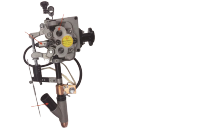

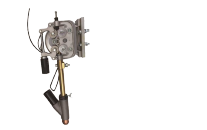

AH-1 SubArc Welding Head

- The pre-selection of nominal values for welding current, arc voltage and speed in coordination with the SubArc-1000XD/1250XD power source ensures a high degree of automation;

- The AH-1 welding head has an automatic ignition and automatic burn-back with withdraw for an optimized welding process;

- The welding head also has adjustment to angle forward or backwards by up to 45 degrees & side to side by up to 45 degrees;

- All welding heads are equipped with a laser pointer and a mechanical pointer for visual seam tracking. Via a cross support, the AH-1 can be manually positioned with an effective adjusting range of 100mm each;

-

-

Item No SubArc-1000XD SubArc-1250XD Input power 3 phase 380V+/-15% 3 phase 380V+/-15% Rated Output Current/Volatge/Dutuy Cycle 1000A/50V/100% 1250A/50V/100% Output Range CC Mode: 100-1000A CC Mode: 100-1250A CVMode: 10-50V CVMode: 10-50V Dimensions 960x420x1100MM 960x420x1100MM Weight 85KG 85KG - SubArc Tractor

AT-1

AT-2

AT-3

AT-4

AT-5

AT-6

SubArc Welding Head

AH-1

AH-1S

AH-2 Twin Arc

AH-4 Strip Cladding

-

-

Q:Are you a factory or a trading company?

A: We are factory with more than 10 years manufacturing experience and we provide perfect OEM and after-sale service.

Q:How can I pay my order?

A: We accept T/T, Western Union, Alibaba Trade Assurance payments. For those orders less than 1000USD, we accept PayPal to pay.

Q:How about your warranty?

A: We offer 3-year product life guarantee ,and a generous 1 year warranty on al purchases that begins with the bill of lading.

Q: Do you have a CE certificate?

A: For every model of machine, it has a CE certificate.

Q:How can I get the quotation?

A: We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price,please send the message on trade management or call us directly

- Tel

- *Title

- *Content

- Loading...