Tips&Tricks

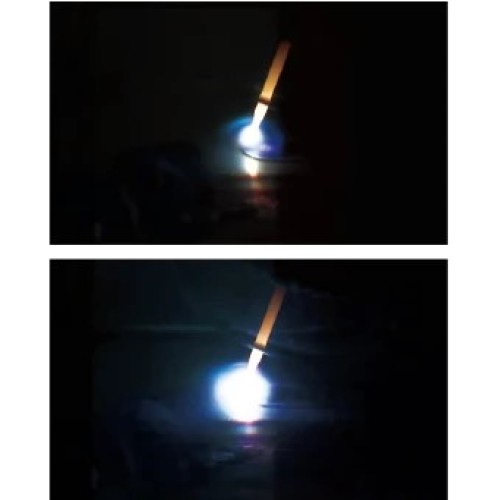

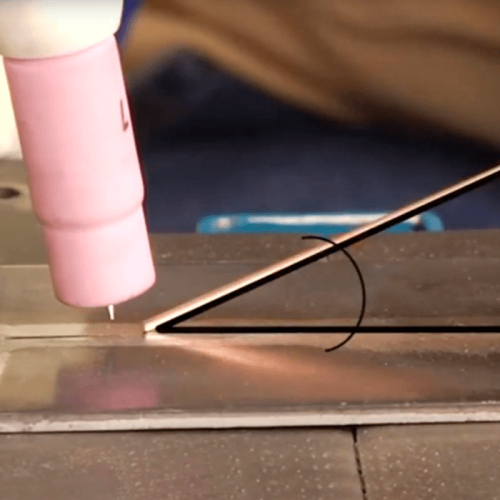

- LEARN How to AC TIG Weld 3mm Aluminum by AluTIG-250HDAC TIGMar 16,2021

3mm Aluminum

Welding current: 145A

AC Frequency: 54Hz

AC Balance: -15%

AC Amplitude: -15%

With TOPWELL Gas-Lens - TOPWELL AC TIG Welding PerformanceAC TIGJan 13,2021

3mm Aluminum

Welding current: 158A

AC Frequency: 132Hz

AC Balance: -5%

AC Amplitude: 3%

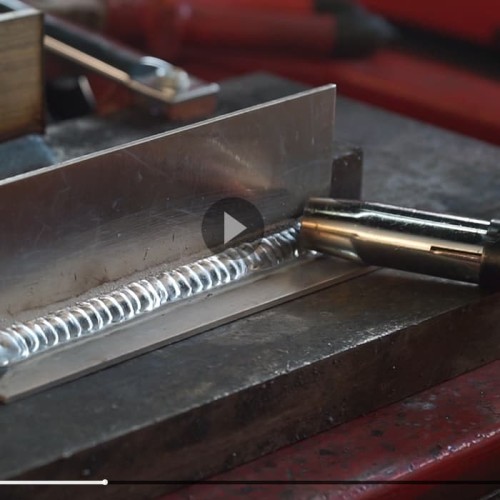

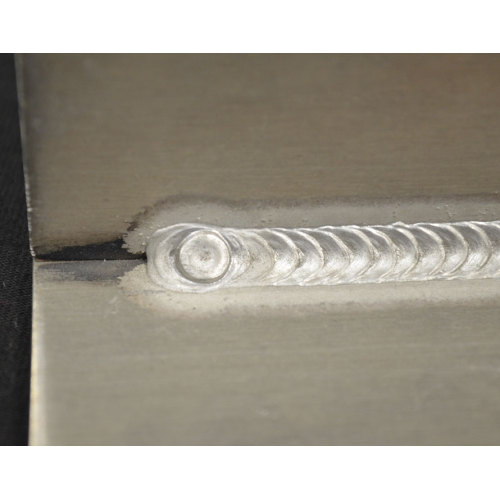

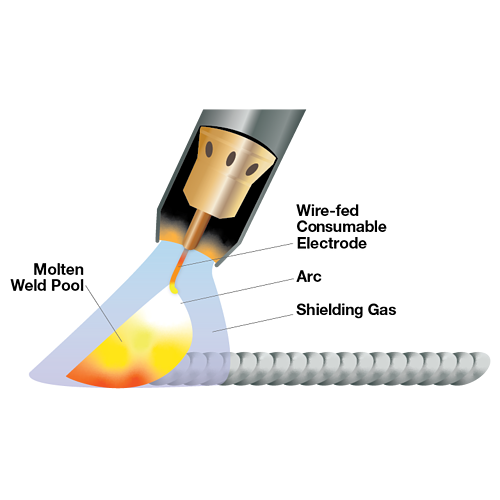

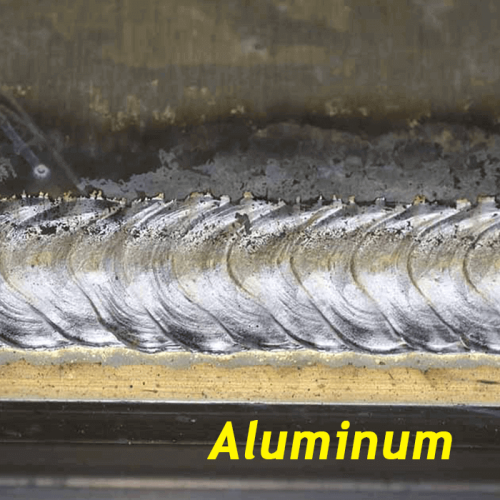

With TOPWELL Gas-Lens - LEARN How to Double Pulse MIG Weld 2mm Aluminumby ProMIG-250SYN DPulseSynergy Double Pulse MIG processNov 16,2020

1.0mm 5356 Aluminum wire

2mm aluminum plate

Job number: 802

Welding current: 78A

By TOPWELL ProMIG-250SYN DPulse

Visit our website for more details:

http://cn-topwell.com/ProMIG-250SYN%20DPulse-Overview.html

Contact us by email: sales@topwellwelders.com - How to Weld Aluminum With a Stick Welder – Detailed Guide(Part1)The joining process of two metal elements through melting is known as welding. It is not an easy job. It is pretty much challenging.Jun 30,2020

- How to Weld Aluminum With a Stick Welder – Detailed Guide (Part2)The joining process of two metal elements through melting is known as welding. It is not an easy job. It is pretty much challenging.Jun 30,2020

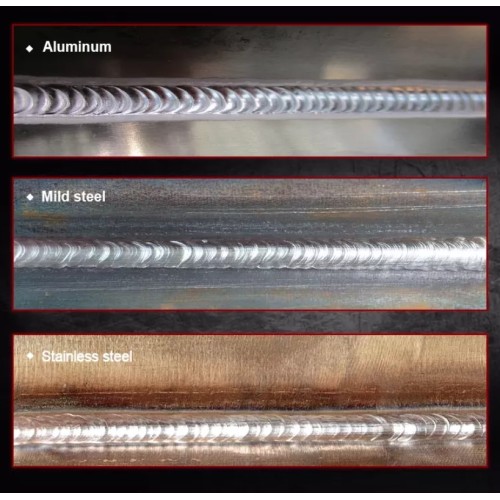

- Ten differences bwteen Aluminum and Stainless SteelAluminum and Stainless Steel might look similar, but they are actually quite different. Keep these 10 differences in mind when deciding which type of metal to use in your next project:Jan 14,2020

- WELDING PROCESSES FOR STAINLESS STEELWarped metal, charcoal-colored welds, and frustration; these are some of the things that can happen when welding stainless steel.Jan 14,2020

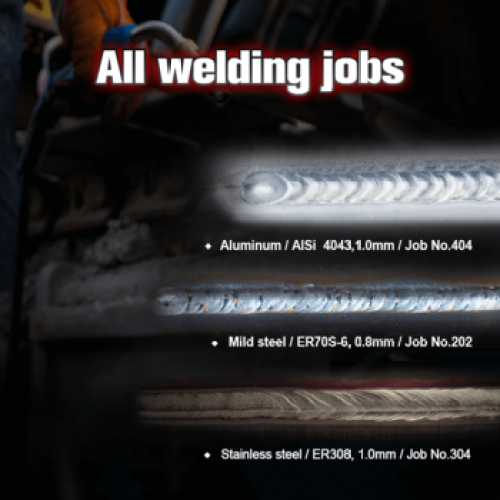

- Aluminum MIG WeldingAlways read and follow the safety precautions and operational instructions in your owner's manual.Jan 10,2020

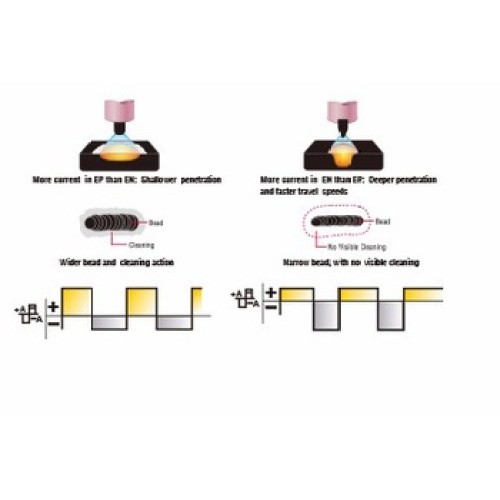

- What is Pulse MIG?Pulsed MIG/MAG welding is a variant of the conventional MIG/MAG welding process in which the current is pulsed. Pulsing was introduced originally for control of metal transfer at low mean current levels by imposing short duration high current pulses. The cycle consists of applying the repeated pulse current over a constant background current:Jan 3,2020

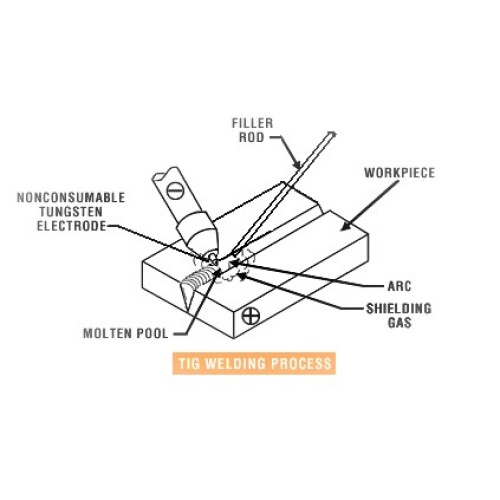

- An introduction to TIG weldingOf all the arc welding processes, TIG (tungsten inert gas) welding is capable of achieving the highest quality welds and is the most versatile in terms of what can be welded and the position of the welds. As in most industrial processes, however, quality comes at the expense of time and TIG is generally slower than MIG or MMA welding. But, where weld integrity is critical, production engineers are prepared to accept the additional process time.Dec 27,2019

- Correct Contact Tip Recess Can Improve Welding EfficiencyIn many cases, MIG gun consumables may be an afterthought in the welding process, as concerns with equipment, workflow, part design and more dominate the attention of welding operators, supervisors and others involved in the operation. Yet, these components — particularly contact tips — can have a significant impact on welding performance.Dec 27,2019

- TIG Welders Require High-Level SkillsTIG Welders fall into three categories: light, industrial, and heavy dutyDec 13,2019

- WHY MIG WELDING IS BETTER THAN TIG WELDING?Arc welding processes are as varied as the work pieces they create, and choosing the right one is vital to your project’s success. While MIG and TIG welding both form the weld using an electric arc, the techniques are quite different, and choosing the wrong one can lead to more than one headache. Read on for the reasons you may want to choose MIG welding vs. TIG welding.Dec 11,2019

- WHEN DO I USE TIG WELDING?Your use of MIG or TIG welding could be the difference in your project that takes it to the next level. You could greatly reduce the time and effort spent making it and improve the quality and durability of the final product.Dec 6,2019

- When do I use MIG welding ?Your use of MIG or TIG welding could be the difference in your project that takes it to the next level. You could greatly reduce the time and effort spent making it and improve the quality and durability of the final product.Dec 4,2019

- AC/DC How to Weld with Stick and TIG on Alternating CurrentAC versus DC is a long held debate. Is it better for a current flow to be unidirectional or alternating from positive to negative? In the end, DC is best for MIG welding and AC is best for TIG welding. AC is also suitable for stick welding. You will have to take some precautions. In any case, electricity is like fire and money; a wonderful servant but a terrible master. Use it wisely and you can be proud of a job well done.Nov 15,2019

- 7 Tips to Improve Your MIG Welding SkillsThe following 7 tips will not only improve your overall technique, but they will help to keep you safe on the job.Nov 7,2019

- Welding Tips-Stick WeldingThese welding tips are meant to be helpful hints. See your equipment Owner’s Manual for all safety and operational information.Oct 18,2019

- Welding Tips-TIG WeldingThese welding tips are meant to be helpful hints. See your equipment Owner’s Manual for all safety and operational information.Oct 15,2019

- Welding Tips-Aluminum MIG WeldingThese welding tips are meant to be helpful hints. See your equipment Owner’s Manual for all safety and operational information.Oct 12,2019

- Welding Tips-MIG WeldingThese welding tips are meant to be helpful hints. See your equipment Owner’s Manual for all safety and operational information.Oct 9,2019

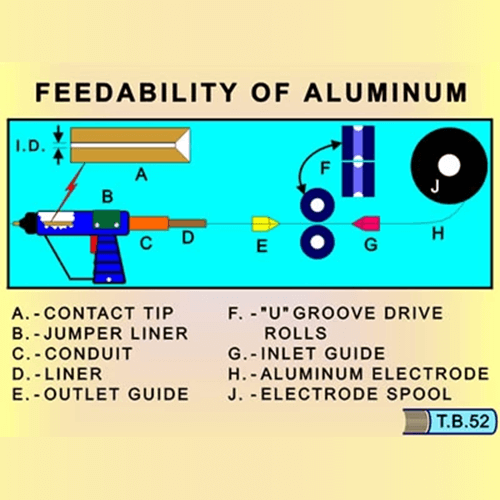

- Feedability in GMAW Welding of AluminumA – Feedability is probably the most common problem experienced when moving from GMAW welding of steel to GMAW welding of aluminum.Aug 24,2018

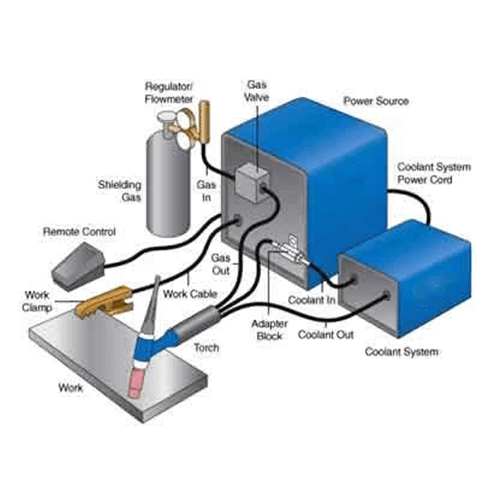

- How do I set up my TIG welder?See your Owner's Manual for complete safety, set-up and installation procedures. The following diagram and instructions show a typical TIG welding system and connections.Oct 25,2017